|

April 2007 |

||||

| Contact Angle on Diamonds | ||||

|

This past month I made contact with an

old-time ramé-hart customer who has a classic ramé-hart Model 100 NRL

Contact Angle Goniometer which he uses to study contact angles on

diamonds and other gems. This customer is Martin Haske, an MIT-trained

engineer who worked on precision inertial and stellar inertial guidance

systems used both in the Apollo and Fleet Ballistic Missile programs

before becoming a professional gemologist. Mr. Haske developed the

Adamas software used by gemologists to identify and grade gems. He has

also developed the SAS2000 Spectrophotometer Analysis System for diamond

color grading. He has a passionate interest in learning about and

discovering new ways to characterize diamonds and other gems. You can

learn more about these advances in gemology at his website:

http://www.adamasgem.org/

The idea of measuring the contact angle of water on inorganic minerals as well as different diamond substitutes dates back at least 30 years. In fact, Mr. Haske contacted us in part looking for a copy of an article from the Winter 1977 copy of GEM & GEMOLOGY journal -- which we happened to have in our library. The article reflects the work of Drs. K. Nassau and H. Schonhorn which was conducted at Bell Labs in Murray Hill, New Jersey, during the 1970's. In their study, they pointed out that diamond substitutes have a contact angle quite different from a genuine diamond, but that irradiation can greatly alter the contact angle by modifying a thin surface layer. One curious characteristic of a real diamond is that it's hydrophobic -- that is, not easily wetted with water. In the mines of South Africa, they use a primitive but effective separation technique wherein crushed rock is washed with water over a bed of grease. The diamonds will adhere to the grease while the other minerals will wash away. There existed a need for a way to identify diamonds and distinguish genuine diamonds from look-alikes. The hardness test (using a tungsten carbide point) will scratch everything -- except a real diamond. The other tests included a reflectometer, refractometer, and specific gravity check. Each of these tests have there own limits. So it was proposed that a Contact Angle (CA) test be developed whereby a simple non-destructive measurement could be taken to assist in the identification of diamond and diamond look-alikes.

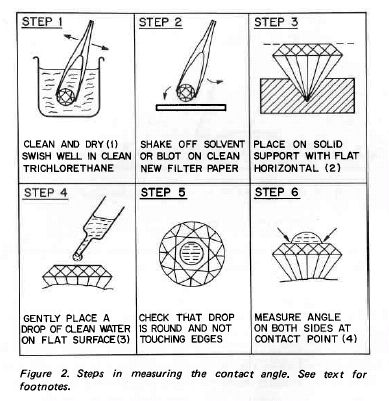

The test involved the preparation and measurement of CA as detailed in the 6 steps as shown above. The cleaning step was found to be quite important as most of the errors could be traced back to contaminants or films of grease or soap. The test called for a ramé-hart Model A-100. Today this test could be done on a current generation Model 100-F0 or any other model. The determined CA range for genuine diamond is 47-55° (according to Nassau and Schonhorn). Cubic Zirconia was determined to have a CA from 70-90°. Many other diamond substitutes were found to have CA values higher than 60°. It was discovered, however, that in some cases gems (including diamonds) that had been irradiated exhibited lower contact angles -- which could lead to misidentification. In every case however, these samples -- when polished (to remove the effects of irradiation) and reexamined -- measured as expected. And so, the measurement of CA, it was concluded, can be used alongside other tests to assist gemologists and appraisers in the identification and authentication of diamonds and other gems. If you are interested in a complete copy of the original article, please contact us.

|

||||