|

ramé-hart instrument co. August 2014 Newsletter |

| Ten Contact Angle Myths Busted |

|

Over the years as I've worked with

customers and potential customers on contact angle solutions, I've heard

each of the bold statements below more than once. My objective this

month is to highlight the top ten contact angle myths that I've come

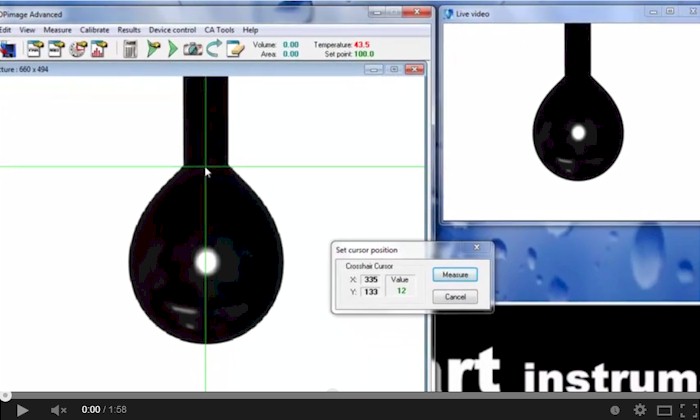

across and debunk them once and for all. Myth 1: As roughness increases, contact angle decreases. This is true for most surfaces - but only because most surfaces are hydrophilic with a contact angle under 90°. However, on hydrophobic surfaces (with a contact angle greater than 90°) the contact angle will increase as the surface roughness increases. For a more detailed discussion of this principle, see our September 2010 Newsletter. Myth 2: Drop volume does not matter; the contact angle should always measure the same. On an ideal smooth surface, this is generally true...so long as the drop volume does not exceed about 8µL, the point at which gravity begins to affect wetting behavior and thus contact angle. However, most surfaces are not ideal. Abraham Marmur has demonstrated that as contact angle hysteresis increases so too does the effect that drop volume has on the contact angle.1 The best practice is to pick a drop volume that works well (typically between 1 and 8µL) and keep the drop volume constant from one sample or location to the next. Use our Automated Dispensing System to improve drop volume repeatability. Myth 3: Self-cleaning means hydrophobic. Most self-cleaning surfaces are in fact hydrophobic: the wiperless windshield (May 2014 Newsletter), self-cleaning Army fatigues (December 2013 Newsletter), and my Puma Clyde suede sneakers (August 2013 Newsletter). However, another class of self-cleaning surfaces relies on a hydrophilic effect. These surfaces (typically glass) are coated with titanium dioxide which promotes a chemical breakdown of dirt by photocatalysis. The dirt is then washed away by rain which forms as a thin layer due to the superior wetting properties of the surface coating. Myth 4: Evaporation is the reason for change in water contact angle over time. As it turns out, evaporation is just one of a number of factors that can explain the change in water contact angle over time. There are at least a dozen reasons for this behavior - including absorption, contact line friction, and chemical reaction. They are summarized here: July 2012 Newsletter. Myth 5: The surface energy of a surface is what drives the contact angle. This is not the whole picture. According to Young's equation, the contact angle depends on both the surface energy of the solid as well as the surface tension of the liquid. While the contact angles of different liquids will measure differently on a given surface, the surface energy doesn't change. In fact, surface energy is technically independent of the liquid used to measure it. Myth 6: It's not possible to distinguish between the wetting properties of surfaces when complete or near complete wetting occurs. When a sessile drop spreads out with a contact angle of 0, we say that complete wetting is occurring. However, complete wetting is rather rare and in most cases, near complete wetting is actually what's happening. The contact angle is under 2°. When using the traditional sessile drop profile method, yes, it's difficult and in most cases impossible to quantify wetting properties when the contact angle is near zero. In these cases we have two methods in our toolbox: First, with our optional Overhead Optical Imaging Kit (p/n 100-31) we are able to calculate contact angle by looking at the top view of the sessile drop. This method works especially well with superhydrophilic surfaces when the contact angle is near zero. Second, we can use the Environmental Fixture (p/n 100-14) and an inverted needle (p/n 100-10-13-22) to measure the contact angle of the captive bubble. This is done by immersing the solid in a liquid and then producing an inverted sessile drop of air on the underside of the sample and then measuring the contact angle. If you are using the Contact Angle Tool in DROPimage, simply go to the Options menu in the CA Tool and under Phase Options, check on Captive Bubble. Soft contact lenses which are made of hydrogels are often measured using this method. Myth 7: If the static contact angle is identical for two different surfaces, that means that their wetting properties are also identical. Not so fast. Static contact angle only tells you part of the story. Consider Samples A and B: they exhibit the same static contact angle of 60°. However, when we measure the advancing and receding contact angles using the tilting base method, we observe that Sample A rolls off at a tilt angle of 30° and has a low contact angle hysteresis of only 4°. Sample B, by contrast, stays on the surface all the way to a 90° tilt angle and exhibits a hysteresis of 9°. From this additional test, we conclude that the Sample A surface, with a lower contact angle hysteresis, is more homogenous with regard to both chemical composition as well as structure. Myth 8: A liquid with a higher viscosity will always have a higher contact angle than a lower viscosity liquid on the same surface. This conclusion seems intuitive...but it's flawed. If you recall, contact angle, as described by the Young equation, is a function of the surface tension of the liquid and the surface energy of the solid. While a drop of a higher viscosity liquid may take longer to reach equilibrium, the surface tension is not necessarily higher or lower than a liquid with a lower viscosity. We established in our February 2014 Newsletter that there really is no direct or reliable correlation between surface tension and viscosity. Myth 9: People who include the temperature with their contact angle reporting are just being overly officious. As discussed above, one of the forces in Young's equation that defines the contact angle is the surface tension of the test liquid. A liquid's surface tension is highly sensitive to temperature. In the video below, you will observe that as the temperature is increased, the surface tension of the liquid decreases. By extension, contact angle is also sensitive to temperature. In general, when temperature is increased, contact angle decreases. For pure liquids, formulas are often used to correct for the effect of temperature on surface tension.

Myth 10: All contact angle measuring devices are created equal. If you have ever used a system that projects a shadow of a drop onto a small screen which requires you to eyeball the highest point and the three phase line in order to pass a dial through these points to then estimate the contact angle based on a half angle measurement, then you already know what it means to collect imprecise contact angle data. Likewise, if your tool's software requires you to pick various points along the profile of your drop in order to determine contact angle, you are likely getting only a rough estimate. In order to achieve a high level of precision and repeatability, you will want a system that uses a precision calibration routine to reference the tool's measurements to an object with known dimensional values. You will also want software that will automatically determine the drop profile by a numerical curve fit with extrapolation at the three-phase boundary. A capable edge-tracing and interpolation routine is also necessary and is superior to thresholding and maximum gradient methods. Event logging, temperature logging, tilt angle logging, oscillation and automated dispensing are also important components to a complete system. ramé-hart DROPimage software meets or exceeds all of the essential requirements for contact angle measuring and includes an impressive list of additional features and options for conducting a wide array of time-dependent and advanced surface studies. 1 Abraham Murmur, "Soft contact: measurement and interpretation of contact angles", Soft Matter, 2006, 2, 12-17. (DOI: 10.1039/B514811C) |

|

Pre-built Coaxial Needle |

|

ramé-hart is the premier fabricator of specialty needles including custom coaxial needles. These are used both for advanced surface tension and interfacial tension studies as well as for electrospraying and electrospinning applications. Based on demand, we now offer a prebuilt coaxial needle. This needle features a 26g inner component with a 20g outer component.

A copy of the drawing for this part can be found here: http://www.ramehart.com/pdf/100-10-COAXIAL-2620.pdf. This item is in stock and can be purchased online here: http://www.ramehart.us/pre-built-coaxial-needle/. For more information on our coaxial and triaxial needles, please see: http://www.ramehart.com/coaxial_needles.htm. |

|

Regards,

Carl Clegg |