|

ramé-hart instrument co. September 2014 Newsletter |

| Increasing Durability of Superhydrophobic Surfaces |

|

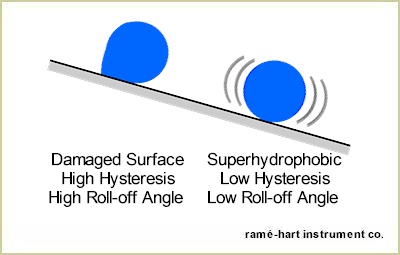

In the past few years, the technologies

and methods used to design and build superhydrophobic surfaces have

blossomed. In recent newsletters, we've highlighted a wide variety of

applications that benefit from non-wetting coatings and surfaces. One

obstacle, however, is making a superhydrophobic surface that will stay

that way over time. The micro and nanoscopic features that are necessary

to make a surface superhydrophobic are by nature fragile and susceptible

to damage and contamination. When a superhydrophobic surface is damaged,

water drops will stick to the surface, and the contact angle hysteresis

and roll-off angle both increase as shown in the graphic below.

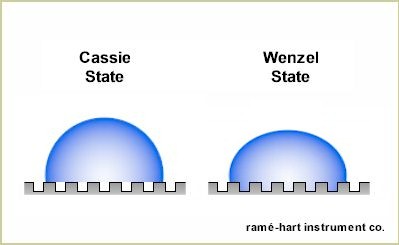

In addition to mechanical wear, contamination can also degrade the efficiency of manmade non-wetting surfaces. Generally, a surface is considered superhydrophobic if the water contact angle is greater than 150° and the drops must roll off easily - that is, have a low roll-off angle which translates to a low hysteresis. Smooth surfaces rarely exhibit contact angles over 120°. In order to decrease wetting and achieve a higher water contact angle, it's necessary to add nano and/or micro scale structure which permits the water drop to sit on top of the roughened surface in what is referred to as a Cassie state. See the graphic below.

The leaf of the Lotus plant is generally accepted as the gold standard in superhydrophobic surface design due to its hierarchical structure expertly optimized for non-wetting. Water drops sit in a Cassie state on top of the micropapillae and can measure close to 180°. In addition to an incredibly high contact angle, the Lotus leaf has another amazing characteristic that researchers are trying to replicate on manmade superhydrophobic surfaces: self-healing. In the case of the Lotus leaf and other hydrophobic surfaces found in nature, biological growth regenerates damaged surfaces and permits non-wetting behavior to persist over the organism's lifespan. Researchers in China have proposed a bio-inspired self-healing superhydrophobic coating.1 During fabrication a surface is embedded with silane. When the surfaces loses its non-wetting properties due to wear, it becomes hydrophilic. The contact between the damaged surface and humidity triggers a release of the embedded silane which restores low surface energy and, in turn, the hydrophobic properties. Surfaces using this method were purposefully scratched with sandpaper only to self-heal multiple times. While this is an important first step, the next step is to find methods that offer self-repairing topography. Another solution to the durability problem is to simply make surfaces that are more durable to start with. Researchers at Oak Ridge National Lab have developed an atomically bonded superhydrophobic coating that is optimized for glass and optical applications.2 In addition to increased durability, the coating is also transparent, anti-reflective and UV-opaque - making it a strong candidate for windows, windshields, glasses, and lenses. Researchers in Australia have developed a self-healing superhydrophobic fabric using a two-step chemical treatment.3 Clothing is subject to frequent washings which are both mechanically and chemically stressful. The treatment can be reactivated simply by heating the fabric to 140° F for as few as five minutes. Other researchers are becoming sensitive to the need for increased durability and surface life expectancy. While the benefits of superhydrophobic surfaces in a wide array of applications are apparent, widespread use is limited by their fragile nature. In addition to mechanical wear, contaminants can also lower their efficacy. Current research is directed at ways to make these surfaces more resilient to failure, longer lasting, and even self-healing. Additionally, by designing a surface to be omniphobic (and not just hydrophobic), contaminants and oils can be repelled before they foul the surface rendering it less efficient at repelling water. It's no longer sufficient to design a surface that is simply superhydrophobic. It must be durable, able to sustain wear and contamination, and be easily repairable. If it can self-heal or regenerate to compensate for damage or fouling, all the closer it comes to the victor's model: the humble Lotus leaf. 1

DOI: 10.1002/anie.201001258 |

|

Our Top 10 Videos |

|

Our videos as of this writing have had over 67,000 views. You can view them here: https://www.youtube.com/user/ramehart/videos. Here are the top ten videos organized by software product: For

DROPimage CA (Model 190): For

DROPimage

Standard (Models 200 & 400) For

DROPimage

Advanced (Models 250 & up) For

Automated Dispensing System If you would like to suggest a topic or task for a new video, please contact us. |

|

Regards,

Carl Clegg |