|

ramé-hart instrument co. November 2014 Newsletter |

| New Product Announcement: Hot Plate |

|

This month we are pleased to announce the

introduction of our new

Hot Plate (100-33-HP) which is coupled with our

Temperature Controller (100-50) to provide a working surface with a

controlled elevated temperature between ambient and 300° C with a

resolution of 0.1° C. Due to its compact design and light weight, the

Hot Plate is supported on all ramé-hart instrument models from 190 up to

790 as well as legacy models such as 100-00. Installation and removal is easy and fast: the Hot Plate mounts to

the standard ramé-hart 3" x 2" leveling stage. And while this

product has been designed as an accessory for any ramé-hart instrument,

it could also be used in stand-alone mode.

If the Hot Plate is used on a system with DROPimage Advanced v2.7 or higher, then temperature logging can be enabled via the USB connection (cable included). Inlet and outlet ports are included for circulating chilled water or a coolant through the base of the Hot Plate in order to bring the temperature down quickly or to below ambient temperature. Note that the Temperature Controller will report and log the temperature whether it's above or below ambient. However, only temperatures above ambient are governed by the controller. If you have more extensive chilled temperature requirements, consider the Peltier Environmental Chamber (100-30). Add the Elevated Temperature Syringe (100-11) to your setup if you are dispensing polymers, solders, or liquids with high melting points. The Hot Plate provides a cost-effective way to study the effects of surface temperature on contact angle and wetting behavior and is compatible with both the Manual and Automated Tilting Base option. For more product information including

pictures, visit |

|

Temperature and Contact Angle |

|

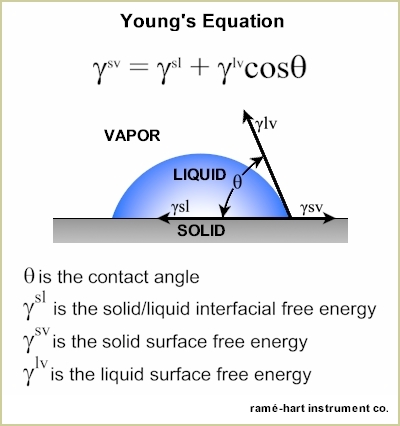

Many factors affect contact angle: surface roughness, chemical homogeneity, surface treatments and coatings, drop volume, humidity, and temperature, to name a few. The Hot Plate enables users to isolate the temperature variable. In research papers, contact angle is often reported with temperature. In most systems, as the temperature increases, the contact angle decreases. The three forces that describe contact angle are integral to Young's equation as shown below.

As the temperature of the surface and drop increases, the molecular thermal activity of the liquid droplet causes the cohesive forces there to weaken. This results in a decrease in surface tension of the drop liquid. Hence we can say that the relative strength of the work of cohesion between water molecules within the drop is weakened by higher temperatures. At the same time the work of adhesion at the solid/liquid interface is some times (but not always) strengthened by an increase in temperature. In many systems, as increasing system temperature weakens the cohesive forces and strengthens the adhesive forces, the resulting outcome is a reduction in contact angle. Naturally, there are exceptions to the rule. For example, on some hydrophobic surfaces an increase in temperature can actually result in an increase in contact angle. While contact angle is a macroscopic metric and while Young's equation deals with macroscopic interactions, it's apparent and worth noting that neither can solely explain microscopic interactions such as the cohesive and adhesive molecular forces that drive surface tension. Notwithstanding, it's meaningful to account for and understand the effects of temperature on contact angle. |

|

Regards,

Carl Clegg |