|

May 2007 |

||||||

| Contact Angle Basics | ||||||

|

Disclosure: If you are already a savvy

surface scientist, you may wish to skip this section as it involves

strictly the basics. For everyone else, including non-technical people,

it's a good introduction to contact angle and general surface science

principles.

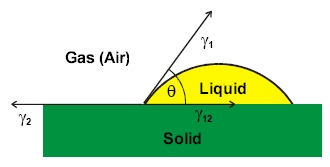

If you place a droplet of water on a flat solid surface and the liquid does not spread, the drop has a contact angle on the solid surface. The balance between the forces are defined by Young's Equation:

where

The contact angle is used often as a metric for determining relative cleanliness. A contaminated surface typically will be more hydrophobic resulting in a larger contact angle. As the contact angle decreases, the wettability and adhesiveness improve and the solid surface free energy increases. The contact angle is an excellent way to measure the efficacy of a cleaning process as even very small amounts of contaminants can be easily detected. Using DROPimage software (except CA), it's possible to calculate Surface Free Energy based on the contact angle data using a number of different methods. Simply making a drop and then measuring it provides valuable data referred to as static contact angle measurement. If you wait a period of time, the contact angle will, in some cases decrease. This can be the result of any one or more of the following: evaporation, relaxation of the liquid molecules, movement of contaminants from the solid to the liquid, a chemical reaction between the solid and the liquid, the liquid being absorbed into the solid, the dissolving of the solid by the liquid. In these cases, it's often of interest to take a static contact angle measurement after making the drop and then taking another measurement some fixed amount of time later (say 30 seconds). A dynamic contact angle measurement is made by measuring the contact angle while simultaneously adding volume to and removing volume from the drop at a fairly slow rate (say 5uL/min). This type of measurement can be carried out with extreme accuracy using our ramé-hart software-driven Automated Dispensing System during which time the dispensing tip is left in the drop as volume is added and removed. The resulting data are used to better understand surface characteristics during wetting and dewetting processes. In a similar fashion, an advancing/receding contact angle measurement is made by leaving the needle in the drop and determining the smallest angle (receding) that can be measured while removing volume but without reducing the area formed by the solid/liquid interface. The advancing angle is measured by adding the maximum volume without any change to the same area. This type of measurement is particularly useful for determining surface free energy.

|

||||||