|

February 2008 |

||||

| Advancing and Receding Contact Angles | ||||

|

Traditionally the static contact angle has

been considered sufficient for quantifying relative wettability,

adhesiveness, and solid surface free energy. Increasingly this single

metric is giving way to understanding the range of contact angles that

can exist given a particular liquid drop on a given solid. The largest

possible drop that can produced without increasing the interfacial area

between the drop and solid produces a contact angle referred to as the

advancing angle. Likewise, as volume is removed from the drop, the

contact angle formed by smallest volume permissible without the

interfacial area shrinking is referred to as the receding angle. The

difference between the advancing and receding contact angle is called

the contact angle hysteresis. For a more detailed discussion of contact

angle methods, see our contributions to this wikipedia article:

http://en.wikipedia.org/wiki/Contact_angle.

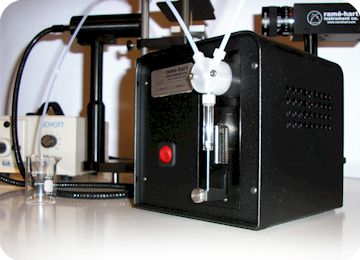

The graphic above illustrates the formation and measurement of an advancing and receding angle using the volumetric expansion and contraction method. Note that this type of measurement can easily be made using any ramé-hart goniometer and the measurement can be automated using any ramé-hart model 200 or up goniometer with the optional Automated Dispensing System. The range of angles between the smallest, receding angle, and the largest, advancing angle, or in other words, the contact angle hysteresis is foretelling of chemical and physical surface heterogeneity, surface roughness, surface cleanliness, surface polarity, and an indicator of drop stability. The smaller the hysteresis, the less stable the drop on the surface is.1 The study of the effectiveness of cleaning methods and surface treatments often reference contact angle hystereses, especially over time, to determine the efficacy of a particular method and it's effectiveness over time.2 Additionally, contact angle hystereses are often used to characterize and facility the design of superhydrophobic surfaces.3 Many consider the contact angle hysteresis more important than the single highest static contact angle in measuring superhydrophobicity. Many of our customers measure advancing and receding angles to quantify surface roughness.4 A smooth surface which is chemically homogeneous will measure a contact angle hysteresis close to zero. As the hysteresis increases, the surface exhibits increased roughness or more chemical heterogeneity. So of course as the surface heterogeneity decreases, so too does the hysteresis. Another and perhaps more traditional method for measuring advancing and receding angles is to use a tilting base. With this method a static drop is dispensed on the solid and the entire instrument is tilted from 0° to as great as 90°. At the point just before the drop rolls off the left and right angles are measured. If you are tilting to the right as shown in the picture in the next section for example, the left angle is the receding angle while the right contact angle (which is larger) is the advancing angle. One additional measurement which is valuable to researchers is the roll-off angle, the point at which the drop can no longer hold on. Superhydrophobicity, in addition to exhibiting a higher than average contact angle, also exhibits very low roll-off angle. The tilting base method is particularly adept at capturing this dimension. Some also consider the tilting base method over the captive bubble method since the drop is undisturbed by the insertion of a needle which may affect the quality of data collected, especially for small drops. Landers5 determined that the tilting base method provided statistically more reliable data while the captive bubble method underestimated the advancing angle and overestimated the receding angle. Experience has shown that variations in drop size and needle diameter affect the outcome of captive bubble studies. A tensiometer using the Wilhelmy Plate or DuNoüy Ring method can also measure advancing and receding angles. However, the primary challenge with this method is resizing your solid to conform the restricting geometric requirements of the system. Additionally, large quantities of the test liquid are required in order to sufficiently submerse the solid and the solid must enter and exit the liquid perfectly perpendicularly. The use of a goniometer to measure advancing and receding contact angles overcomes these challenges: only a small drop of the liquid is required, the sample can be of any geometry as long as there is a flat -- or even semi-flat surface somewhere -- and the perpendicularity challenge is a non-issue. Notes |

||||

|

||||