|

November 2010 |

|||||||||||

| Custom Instruments | |||||||||||

|

At ramé-hart we attempt to provide the widest array of tools to fit every requirement and budget. Our simplest instrument, for example, Model 190, measures contact angles precisely and quickly. Our Model 590, by contrast, sells for nearly 3.5 times as much but, in addition to measuring contact angle, can also measure surface energy, surface tension, interfacial tension, advancing and receding contact angles, contact angle hysteresis, roll-off angle, and can perform myriad types of dynamic and time-dependent studies. Despite the wide range of tools and modular accessories to choose from, we find that about one in ten of our customers have an application that requires an apparatus beyond what we can build with a standard instrument and standard modular accessories. For these unusual applications, we offer a custom build service. Consider the following three applications:

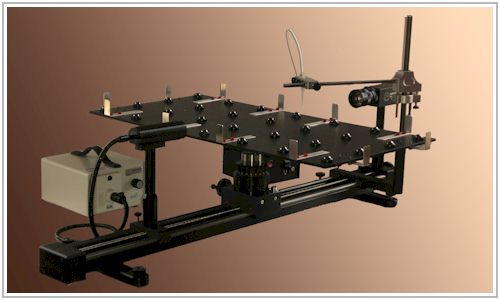

A customer with a need for a contact angle goniometer to test wetting at various locations on a large 14.5" x 20" glass sample requires the various locations to be tested without handling the substrate - that is, the instrument must allow for all locations to be measured without removing the sample from the support. With our standard equipment, we can accommodate a sample up to 13.625" diameter. In order to accommodate this large sample, we designed a custom support frame with guide fingers which allow the sample to be repositioned as required along the y-axis. See Figure 1 above. We also built an optical bench longer than standard in order to move the light source, stage, and camera to their requisite locations on the x-axis. Lastly, we redesigned the microsyringe fixture with a long arm so it could reach out over the sample to all required locations. This custom order was designed, approved by the customer, and delivered within 10 weeks of receipt of the original purchase order.

A customer with a circular disk substrate approximately 1" in diameter has the need to test the contact angle along the edge of their sample by rotating it 10° between measurements. They also need to take these measurements at temperatures between ambient and 240° C. Our standard Environmental Chamber (p/n 100-07) is the ideal solution for this application - except to rotate the sample, the cover would need to be removed and the sample would then need to be relocated manually. Not only is the position inaccurate, but the environmental conditions in the chamber are disturbed and the time it takes for the temperature to stabilize makes for very slow data collection. To overcome these issues, we designed a small rotating support which we mounted inside of our standard Environmental Chamber (100-07). See Figure 2 above. The materials selected are rated to handle temperatures up to 300° C. The goniometer and custom chamber were delivered 8 weeks after receipt of the purchase order. Standard delivery without customization is 4 weeks for most systems.

A customer needs to measure large heavy metal samples. Our standard leveling stage proved to be too small. We designed and built not only an oversize stage but also a heavy-duty leveling base to support the weight of the samples. Delivery for this instrument was 9 weeks including engineering, design review and approval by the customer and fabrication. Each part in addition to being machined, must be checked, finished, and then sent out for plating. Aluminum parts are anodized which makes them hard and strong and in some cases black. Stainless steel parts are sometimes chrome-plated and other times passivated. Our instruments are made primarily of aluminum and stainless steel parts. We also use PTFE, Frelon and ceramic coatings on the shafts and bushings, copper, and bronze alloys such as Oilite. For more pictures of various custom instruments we've built, please visit the newest page on our website here: http://www.ramehart.com/custom.htm

If you have a unique application, let us

know how we can build a new system or modify an existing instrument to

meet your requirements. |

|||||||||||

| FAQ | |||||||||||

|

Here are the most frequently asked questions regarding our custom build service: Q: What do I need to provide

ramé-hart with in order to get a quotation for a custom instrument. Q: How long will it take you

to build my custom tool? Q: How will I know that you

will provide what we need? Q: How are you able to make

custom instruments so quickly? Q: Why should we choose

ramé-hart to build a custom instrument for us? Don't hesitate to let us know how we can work with you on a custom solution that will meet your requirements and be within budget. |

|||||||||||

|

|||||||||||