|

March 2011 |

|

| Making Lexan Hydrophobic - Part 2 | |

|

This article is a follow up to last month's "Superhydrophic Motorcycle" story. Click here to read Part 1: http://www.ramehart.com/newsletters/2011-02_news.htm. Our study involved looking at different surface treatments for improving hydrophobicity on polycarbonate motorcycle face shields and windscreens with the goal toward improving visibility in rainy riding conditions.

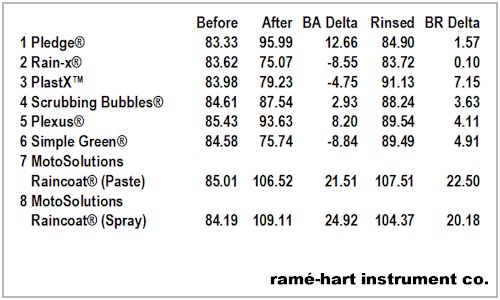

We received a number of responses. The first suggestion was to look into a product called NeverWet™. We tried to purchase a sample but we were unable to locate it anywhere. So, we contacted the company directly and asked for a small sample. They declined; so we did not test their product. However, we found a cool toilet plunger that uses the NeverWet™ coating. It's called the Clear-N-Clean Plunger. We'll have to see if we can get our hands on one so we can review it in a future newsletter. Another suggestion was to try a product called Raincoat®, made by MotoSolutions. We obtained a sample of the paste version as well as a spray-on version from the manufacturer and replicated the testing we did last month with (6) other surface treatment products. We were surprised to see an an increase in contact angle (BA Delta) of over 21° after applying the paste treatment to an untreated Lexan surface. The spray version of the coating improved the contact angle by nearly 25°. After the 5-minute rinse, the paste coating actually improved slightly while the spray-on coating lost some of its hydrophobicity. See BR Delta in the chart below which is the difference between the original contact angle and then the contact angle after treatment and rinse. Overall, the Raincoat® performed better than any of the previously tested products.

The paste version of Raincoat® is the most difficult of all (8) coatings to apply. It requires rubbing on, waiting several minutes, and then rubbing off. The rubbing off takes some effort. The spray-on version goes on easy but, after several minutes, must be rubbed off as well. However, it takes somewhat less effort compared to the paste version. Next, I applied Raincoat®

to the polycarbonate face shield on

my motorcycle helmet. It looks the same but water rolls off noticeably

easier. There's a chance of showers on Saturday...so I may be going on a

little road trip to put Raincoat®

to the test. |

|

| DROPimage Advanced v2.5 | |

|

We're pleased to announce the release of v2.5 of our DROPimage Advanced software. On the surface, it looks and feels much like the previous version, 2.4. However, we made significant updates to the internal code and structure of the program in order to accommodate high-speed cameras. We now include support for the high-speed Gigabit Ethernet interface which is 10 times faster than the original IEEE1394 FireWire interface. In addition, we've rewritten the code for making videos and now support selectable Codecs for maximum compression of user-generated video files. Videos can be played back using the internal video viewer or any AVI player such as Windows Media Player. Most importantly, DROPimage Advanced v2.5 is the foundation for a new generation of ramé-hart instruments built on the newest and most robust technology available. Beginning this month, all new systems with DROPimage Advanced are shipping with v2.5. In the months ahead we will be offering one or more high-speed camera options as well as other new cameras options. Stay tuned for more details coming soon... |

|

|

|