|

September 2012 |

| Methods for Measuring Contact Angle |

|

There are many ways in which contact angle can be and have been

measured. Today contact angle is primarily measured using camera-based

software-controlled goniometry. Some methods presented in this

newsletter were developed and optimized in a time before today's

technology was available. These methods while included will be presented

from an informational perspective and for a historical purpose without

suggestion that they be employed today. Please note also that some of

the methods are primarily used to measure surface tension. However,

contact angle can also be derived or calculated as a secondary function

using these methods.

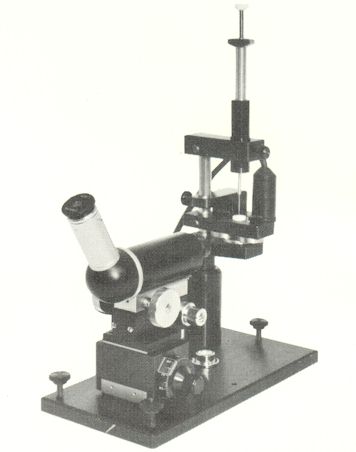

Manual Optical Goniometer The traditional method for measuring contact angle involves the use of a manual optical goniometer consisting of a backlight, specimen stage, and optical microscope – all mounted on an optical bench. The user locates a sessile drop on their sample through the microscope and with the use of a protractor which is built into the microscope, dials in and measures the contact angle.

The ramé-hart Model A100, shown in the picture above was the world's first mass produced contact angle goniometer. ramé-hart Model A100 and its successor, Model 100-00, enjoyed a useful lifespan of nearly fifty years with thousands produced during its life. Many hundreds of units are still in use today throughout the world. Software-controlled Camera-based Goniometer The manual optical contact angle goniometer has largely been replaced by today's generation of software-controlled contact angle tools which replace the microscope of the manual systems with a camera. The first generation of camera-based systems (1990's to early 2000's) employed analog cameras. Today's current systems feature digital cameras. Instead of looking through the microscope at the drop profile, the camera takes a picture of the profile. The analysis software then fits the image to a profile and automatically calculates the contact angle. The entire process is much more automated and less subjective. Repeatability with these software-driven tools is also far superior to the optical systems they replace. Perhaps the most compelling advantage to the software-controlled contact angle tool is the ability to greatly enhance its usability by adding tools for calculating surface energy, surface tension, interfacial tension, and for performing time-dependant and dynamic studies with automated dispensing and tilting functions for determining advancing and receding contact angle measurements, surface dilatational elasticity, absorption, dynamic wetting, and other metrics which were difficult or impossible to do on the manual optical tool. Additional options are available for controlling the environmental conditions such as temperature and humidity. Wilhelmy Plate Method The Wilhelmy plate method was originally designed to measure surface tension. The Wilhelmy plate is a thin substrate, usually platinum or glass, which is lowered into a liquid to measure surface tension. The Wilhelmy plate can also be used to measure contact angle. This is done two different ways. One way is to set up two plates with the same perimeter and geometry – one is a reference solid with known properties and the other is the test surface. The force required to pull each of the samples from the same liquid is measured and from this data the contact angle of the test solid can be derived from the difference in work of adhesion of the two surfaces. The other method, called the capillary rise method, relies on a vertical wall to measure contact angle. A test plate is lowered into a liquid and as it is pulled out the height of the meniscus is then precisely measured. By using the Young-Laplace equation, the contact angle can be calculated. The Wilhelmy plate method is not very practical for most applications as both surface roughness and lack of surface homogeneity make repeatability poor. It's also difficult in many cases to fabricate test samples that conform to the strict dimensional requirements of the plate. A buoyancy factor must also be factored in. Half Angle Method Another method that was used for some time was the "half angle method". This technique involved projecting the profile of a drop onto a small screen on which a modified protractor is used to find the angle which is formed between the baseline and the line which passes through the three-phase line and the apex of the drop. This angle is then aligned with the estimated actual contact angle which is reported on the protractor. The half angle contact angle tool was inexpensive to produce but the accuracy was quite poor rendering this type of device to be of limited utility. Wetomoter Another method for measuring wetting behavior involves the use of an instrument called a wetometer. The principle behind this legacy device involves a capillary tube which is used to dispense a precise fixed volume of liquid onto a surface. The resulting sessile drop is then located in a microscope and a dial is used to precisely measure the height of the drop. While this device does not report the contact angle, it does report the drop height and knowing the volume of the drop, the contact angle can geometrically be derived.

The wetometer was well-suited for quality control applications where a simple pass/fail tool was needed to evaluate "spreadability" of various liquids on a surface. ramé-hart, the manufacturer of the Wetometer, produced this patented device for nearly 20 years during the 1970's and 1980's. Newer technology eventually replaced the wetometer. Dyne Test Perhaps the most inexpensive way to measure wettability for a limited variety of substrates is to use a set of Dyne test pens. These do not measure contact angle per se but will give an estimate of the surface energy of a solid. A test pen is used to mark a surface. The ink from the pen will either bead up into small drops or wet out in a continuous film and remain so for a specified time period. The tester will use a series of different pens until the correct value can be determined. Test pens are available for only a limited range of surface energy values (typically 30 to 60 mN/m) and only work on a limited range of substrates. Dyne pens are used frequently by printers as a quality control tool. In order for ink adhesion to occur a sufficiently high surface energy needs to be present. This method is low cost but the inks are toxic which make this method not suitable for many applications. Single Fiber Contact Angle There are two common methods for measuring contact angle on single fibers. The first method involves lowering the fiber into a vessel of liquid. The fiber is then slowly removed and the contact angle formed by the resulting meniscus is measured geometrically by analyzing an image of the profile of the fiber and water. This method is possible using a suitable camera-based goniometer. In some cases, it may also be possible to position a sessile drop on a fiber and then measure the resulting contact angle. The second method, called the single fiber Wilhelmy method, uses a tensiometer. The fiber is lowered into the test liquid and the force required to move the fiber is precisely measured by the instrument. Like the Wilhelmy plate method, the forces required to move the fiber are captured. The software then – taking into account the buoyancy force, the mass of the probe and other factors – calculates the wetting force from which the advancing and receding contact angles are derived. Powder Contact Angle There are three ways that are used to measure the contact angle of powders. The first method involves compressing the powder using a press into a tablet. The traditional sessile drop contact angle method is then used to measure the contact angle. Since the compressed powder is often porous, a high speed camera can be used to capture the contact angle at inception before absorption occurs. In some cases the drop will be consumed by the compressed powder surface so fast that it's not possible to collect results that are meaningful. When the drop remains static or dissipates slowly, the goniometric method is ideal. The second method involves using tape to capture a layer of powder particles. The tape is then treated like a plate and the Wilhelmy plate method (described earlier in this newsletter) is then used. The third method is called the Washburn (or modified Washburn) method and is named after the Washburn theory which is used to describe the wetting properties of porous solids. According to this theory, when a porous solid meets a liquid, the rise of the liquid into the pores of the solid will follow a particular pattern. To measure the contact angle, the sample powder is placed into a porous powder holder and is then lowered into the test liquid. When it touches, the liquid rises into the powder as a result of capillary forces. The change in mass is recorded over time. Using this information, the contact angle can be derived and the wetting characteristics can be better understood. Du Noüy Ring Method The Du Noüy ring method is primarily used to measure surface tension. This method involves lifting a precisely fabricated ring, typically made of platinum, from a liquid bath. The force required to pull the ring from the liquid is measured and from that value, surface tension can be determined. The contact angle can be derived from the ring dimensions and height of the meniscus. This method is rarely used for contact angle measurement and even for obtaining surface tension, is considered a dated method. Lenard Frame and Paday Rod-pull Methods The Lenard frame and Paday rod-pull methods are similar to the Du Noüy ring method but instead of using a ring, a wire or rod is used. These methods are also used primarily to measure surface tension and are especially useful for pharmaceutical applications and the production of Langmuir-Blodgett films. Fewer correction factors are required for finding the surface tension when compared to the Du Noüy ring method. But for measuring contact angle, their usefulness is limited. Overhead Method The overhead method requires a sessile drop of a precise volume (much like the Wetometer) to be dispensed on the test surface. Instead of looking at the drop profile which is the more common method, the top view is captured and the diameter of the three-phase line is measured. By knowing the drop volume and the three-phase line diameter, the volume can be geometrically calculated. There are two disadvantages to this method. First, it is common to dispense from overhead. And so it's difficult to dispense and also view from the same vantage. Second, if the surface is hydrophobic (greater than 90°), this method will not work since it's not possible to view the three-phase line if the perimeter of the drop from the top view is greater in diameter. Consequently, the overhead method is most suitable for measuring low contact angle on hydrophilic surfaces only. Bottom View Method The bottom view method is similar to the overhead method except the camera is under the drop and looking through the substrate directly at the bottom of the sessile drop. This method overcomes one of the shortfalls of the overhead method: from the bottom view, the three-phase line is visible even with hydrophobic and superhydrophobic samples. However, the bottom view method has very limited utility since it only works on clear flat glass or other substrates which you can clearly see through. Other Methods

Hundreds of US patents have been issued over that past 50 years relating

to contact angle. Many of these patents incorporate interesting and

novel methods not detailed above. However unique and thought-out they

are, most are for a very narrow application or are not commercially

practical. For this reason, we acknowledge their existence but do not

attempt to explain and categorize them in this discussion. |

|

Carl Clegg |