|

ramé-hart instrument co.

February 2013 Newsletter |

| How to Build a Self-Cleaning Surface |

|

If you can imagine all the things that

need to be cleaned, it can be a bit overwhelming: windows, cars, solar

panels, buildings, boats, motorcycles, shower curtains. Now imagine all of the

manpower required to clean all these things. It takes billions of

dollars annually to keep all the things around the globe clean. Now

imagine if you could reduce even a small fraction of all this required

cleaning. All of this imagining helps us appreciate the need for

self-cleaning surfaces. A self-cleaning surface is one that becomes clean simply by getting wet or even just being rained on. As the water rolls off, it takes contaminants with it. While the concept of self-cleaning surfaces has been around for some time, it's only been in the past decade that a few applications have reached the commercial market. In our April 2008 Newsletter we discussed Lotusan paint, a product that will make surfaces self-cleaning. NeverWet, another self-cleaning coating which is being introduced commercially, can be applied to house siding, fabrics, shoes, and toilet plungers. In September 2011, I proposed a self-cleaning toilet. I think we are still waiting for someone to finish that design. Pilkington Glass makes a self-cleaning window using their technology called Pilkington Activ. In short, there are already a handful of commercially available self-cleaning products and coatings on the market.

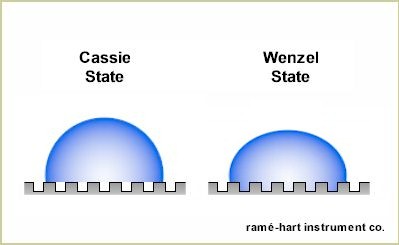

Let me be so bold as to predict that many more self-cleaning products will be commercialized in the near future. Just last month, for example, we introduced to our reader LiquiGlide, a novel product that makes the inside of ketchup bottles self-cleaning. Researchers are vigorously working on many more dozens of self-cleaning products which we will hear more about in the months and years to come. Today our purpose is to offer you a primer on how to build a self-cleaning surface. Follow these guidelines and you could become rich and famously successful. But act now before someone beats you to it. Here are the answers: 1. A self-cleaning surface must be superhydrophobic. Or maybe not? As it turns out, the majority of self-cleaning surfaces are indeed superhydrophobic -- that is, they have very high water contact angles in excess of 150° and usually greater than 160°. However, there is a class of self-cleaning coatings that are hydrophilic. Self-cleaning glass coatings based on titania (titanium dioxide), for example, are hydrophilic. Additionally, these titania-based coatings photocatalyze dirt particles with the help of the sun. Cardinal Glass makes Neat Glass using this technology; so, too, PPG Industries makes SunClean, and Pilkington makes Activ. Note that the remaining points apply to the superhydrophobic variety of self-cleaning surfaces. 2. Don't waste your time on flat surfaces. The highest contact angle you will get might be 110° with something like Teflon. You will need some type of nanoscopic topography in order to reach the necessary level of superhydrophobicity to make your surface self-cleaning. 3. You should consider using a hierarchical structure. Let's face it, no one has these things figured out better than Mother Nature. If you study the Lotus leaf, for example, you will find that it has nanoscopic bumps on top of microscopic protrusions. 4. You need to seek the lowest possible contact angle hysteresis and roll-off angle. To do this, make sure your drop is in a Cassie (or composite) state - sitting on top of the peaks. When the drop is in a Wenzel (or non-composite) state, that is, down in the nooks and crannies, there is too much stickiness and the drop does not want to roll off or move easily. It's tied down to the surface with all its little roots in the surface and more force is required to get it to move.

5. As you design your topography, try to avoid squared off protrusions (like the ones shown in the graphic above). Rather, round them off with hemispherical tips. It will reduce pinning, increase contact angle, and decrease contact angle hysteresis. Also, don't make them too short. Longer protrusions produce more stable superhydrophobic surfaces. Unfortunately, the longer they are the more mechanically challenging the task of making them is. And another consequence of longer protrusions is increased fragility and shorter life. So, good luck with that. 6. Don't rely on surface modification alone. Be sure your material has low surface energy to start with. The hydrophobic properties of the surface are only amplified through surface modification. 7. Field test your creation. You can do a lot of cool things in the lab, but if your new coating loses 80% of its efficacy after a week outdoors (as many such surfaces do), you flunk on robustness. 8. Make sure your self-cleaning surface is safe. A novel coating for a ship hull that prevents barnacles from attaching but also kills fish may be accomplishing its original goal but the negative side affects are unacceptable. Toxic runoff, carcinogens, all bad and to be avoided at all costs. 9. Cost. If your new self-cleaning paint lasts 25 years and saves the property owner $72 per square foot in maintenance costs over that period but the paint costs $90 per square foot to apply, it might not be wildly successful. 10. Make sure your idea is novel. There are so many nanosurface patents already filed, there's a good chance that whatever you do come up with has already been thought of - not by someone any smarter than you, but by someone a little quicker to the draw. Good luck with your design. If you need

help measuring your contact angle, we can help you. Let us know. |

|

Regards,

Carl Clegg |