|

ramé-hart instrument co.

October 2013 Newsletter |

| Contact Angle Hysteresis |

|

We just finished reviewing about three

dozen papers, all written in the past 24 months; many were written by

our customers. Our goal was to identify new trends in contact angle

research. The topic that came in first place of the dozen or so themes

that we picked up on is: contact angle hysteresis. While not a new

discovery or concept, contact angle hysteresis seems to be of increasing

interest to a wide array of researchers.

In theory, we would anticipate that a pure liquid drop on a perfectly flat, smooth and homogenous surface (i.e., an ideal surface) would produce only one possible static contact angle. In the real world, however, most surfaces are far from "ideal". If a small amount of volume is added to a sessile liquid drop on a non-ideal surface, the contact line (three-phase line) may remain pinned as the contact angle increases as a result of the added volume. Likewise, some volume may be removed and the contact angle may decrease while the contact line remains static. Thus there is a range of metastable states with a range of contact angles. The maximum possible contact angle is referred to as the advancing contact angle and, when using the add volume method, is the maximum contact angle that can be achieved before the drop wets and the contact line slips resulting in a lower contact angle. The receding contact angle is the smallest contact angle that can be achieved while volume is being removed before dewetting occurs and the three-phase line slips inward to a smaller diameter. The difference between the advancing (θA) and receding (θR) contact angles is the contact angle hysteresis (H). H = θA - θR The graphic below illustrates the advancing and receding contact angles as measured using the add/remove volume method.

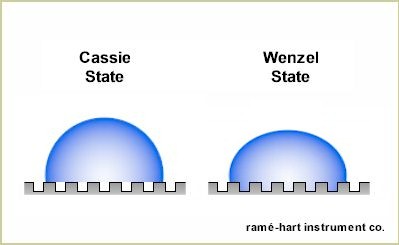

One contributor to contact angle hysteresis is surface roughness. Compare, for example, a piece of sandpaper to a perfectly flat smooth surface. It requires more force (that is, a greater increase in drop volume) to get a drop on the sandpaper to de-pin and wet out than it does for a drop on the smooth surface. In the case of the sandpaper, the drop has to overcome the pinning force caused by all of the nooks and crannies on the surface. Thus we can say that if contact angle hysteresis is small, then surface roughness is low. Caution should be taken, however, since this conclusion only applies to the contact angle in the Wenzel state. On many nanostructured surfaces, the hysteresis may be low while roughness is high but a different set of rules apply to contact angle in a Cassie-Baxter state.

Chemical heterogeneity at the surface level also causes hysteresis. In other words, a chemically homogeneous surface is reflected in a lower contact angle hysteresis. Contaminants and other factors can also affect hysteresis. Another way to quantify hysteresis is to use the tilting base method as shown below. Drops in a Wenzel state with low roll off angles tend to have low hysteresis as well.

Increasingly, researchers are interested not only in measuring, but in controlling hysteresis. For some applications, such as immersion lithography, hysteresis is undesirable and efforts are made to reduce it. For other applications, such as dip coating, hysteresis is good and methods are employed to increase it. There is still some debate on how hysteresis can be controlled, what affects it, and the best way to measure it. What's clear is that if you are looking to study hysteresis, a ramé-hart Automated Goniometer / Tensiometer is a good place to start. Three of our models (290, 295, and 590) ship fully equipped to measure advancing and receding contact angle and hysteresis in an automated fashion using either the add/remove volume method or the tilting base method. All of our instruments can measure hysteresis using the add/remove volume method in a manual mode. Most models can be upgraded with the Automated Dispensing System to automate this type of measurement. Also, a tilting base option is available for all models that do not include one. Contact us for a quotation or more information on our contact angle tools.

|

| Our New Web Store at www.ramehart.us |

|

Ten years ago we launched our first

ecommerce website for spare parts and accessories at

www.ramehartstore.com. It was

somewhat of an experiment and when it first launched we processed only

about three orders a month. We soon learned, however, that our customers

greatly appreciated a way to purchase online spare parts such as light

bulbs, microsyringe assemblies, needles, and parts for the Automated

Dispensing System. Years passed

and soon our volume increased to three orders a week. In

January of 2008 we replaced our web store with a totally new website

- bigger pictures, SSL security, international shipping, etc. Our second

generation web store served us well and has become an increasingly

important way for us to serve our customers. But today we receive as

many as three orders a day and in an effort to offer the best shopping

experience, we've upgraded to our new third-generation webstore which is

now online at www.ramehart.us.

(If you go to the old store

www.ramehartstore.com, it will redirect you to the new site.)

Our new web store features all of the

same products we previously offered plus some new ones. The website is

well organized and ordering has never been easier. The site will scale

to a smart phone or tablet and of course works well on any PC using any

browser. Payment processing is now integrated - so you will be advised

immediately if there is any issue with your credit card. Order

processing on our end is much more efficient and streamlined allowing us

to offer better delivery, improved efficiency, and a wider selection of parts. If you haven't

already, please browse our new web store at

www.ramehart.us. And if you find

something you need, go ahead and order it. |

|

Regards,

Carl Clegg |