|

Visit our website at

www.customspinnerets.com

|

|

|

|

Electrospraying versus Electrospinning |

|

Electrospraying and electrospinning are

related technologies which are used to produce polymer nanomaterials.

They use almost the same apparatus and methods. The key difference

between these two technologies is that electrospraying produces

nanobeads, spherical microparticles deposited on a substrate, while

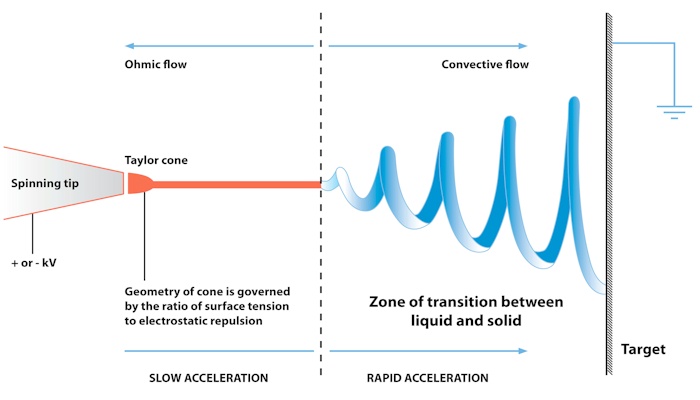

electrospinning produces nanofibers. Electrospraying requires high voltage to be applied to an emitter (aka, spinneret, needle, spinning tip) while a polymer solution is pumped through the emitter. A Taylor cone forms at the tip of the emitter and due to Coulomb repulsive forces, the solution, now in the form of charged microbeads, is dispersed prior to reaching the target surface.

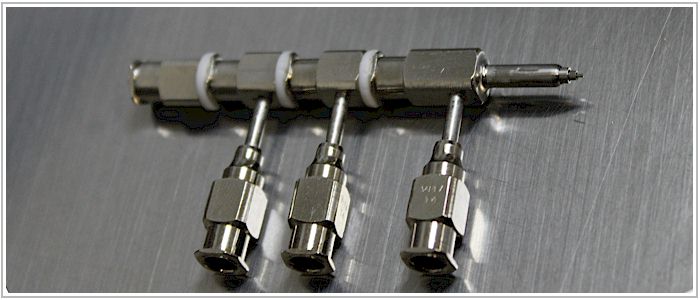

Electrospinning also relies on a polymer liquid to be pumped through a charged spinneret, a Taylor cone is also formed, but by using a different polymer concentration, the cohesive forces in the liquid prevent stream from breaking up. As the stream flows, as shown in the diagram above, it passes from a slower ohmic liquid state to transitional convective state during which the stream accelerates and transitions to a solid fiber prior to deposition on the surface. Coaxial electrospinning relies on two liquids. The properties of the outermost solution control the spinning behavior. The inner solution permit the formation of composite fibers - useful for drug delivery systems and other applications. A third or fourth solution can be added by using a triaxial or quadaxial needle (see photo at top and item 3 in "What's New" section below). ramé-hart is the world leader in the fabrication of custom coaxial needles used for coaxial electrospinning - as well as triaxial and quadaxial needles for more advanced electrospinning. By controlling the spinneret variables, researchers can control the outcome of both electrospinning and electrospraying processes. Our worksheets (see http://www.ramehart.com/pdf/coaxial_worksheet.pdf for coaxial needles and http://www.ramehart.com/pdf/triaxial_worksheet.pdf for triaxial needles) allow maximum flexibility for spinneret design. Our fast turn around for custom coaxial needles (one week) and our in-stock prebuilt coaxial needles (see http://www.customspinnerets.com/#!coaxial/rs9qj) provide maximum flexibility. And if you need something special, we can do that, too. See some of our special orders here http://www.customspinnerets.com/#!gallery/cee5. |

|

What's New |

|

1. If you have not yet visited our new website which we launched in the

Spring, at

www.customspinnerets.com, please check it out.

2. We've increased the number of in-stock ready-to-ship prebuilt coaxial needles from four to six. A copy of the drawing can be found here: http://www.ramehart.com/pdf/coaxial_prebuilt.pdf. These can be ordered online here: http://www.ramehart.us/prebuilt-coaxial-needle/. See coupon below for extra savings. 3. We make quadaxial needles (aka, tetra-axial needles) on a custom basis. See photo at the top of page for sample configuration. If you're interested in this or any other custom configuration, please contact us with your requirements or drawing. |

|

Save on Prebuilt Coaxial Needle |

|

|

|

Thank you for your custom coaxial and

triaxial needle orders. We've worked really hard to be the world's

number one supplier of custom coaxial needles and each day we continue

to work hard to stay there. |

|

Regards,

Carl Clegg |