|

Visit our website at

www.customspinnerets.com

|

| Making Electrospun Nanofibers is Fun |

|

Nanofibers are manmade fibers that have a diameter that is measured in nanometers. There are a variety of methods used to make nanofibers but electrospinning is doubtlessly the most common. Electrospinning is easy to understand and master; it's cost-effective and doesn't require highly advanced equipment. Way back in the 1880s the English physicist Lord Rayleigh studied the state of liquid drops that were charged electrically and observed a spray that would later be named the Taylor Cone. Another British physicist, Charles Vernon Boys published a paper dealing with the production of nanofibers. By 1900, the first US patent was filed for electrospinning. Despite its early discovery, however, it wasn't until the past 30 years that electrospinning has been studied and developed in earnest. Research has accelerated in recent years as opportunities to address challenging medical and other applications have promoted vigorous exploration.

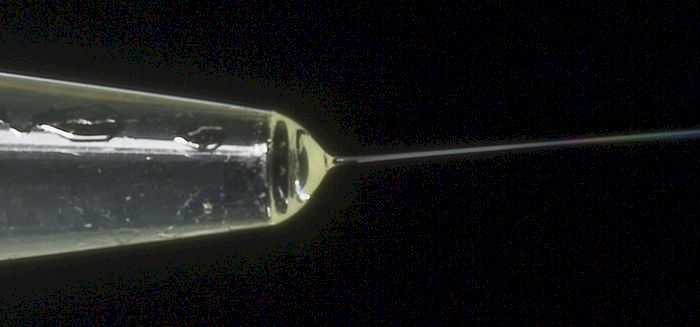

Electrospun fibers can be made from a variety of polymer liquids. When a high voltage is applied to the liquid, the electrostatic repulsive force overcomes the surface tension of the liquid and a drop is stretched into a stream. Molecular cohesion keeps the liquid in a stream which dries in the air becoming a nanofiber. If the liquid breaks up in flight, the result is called electrospraying. The point where the stream forms is called the Taylor Cone.

Current research and electrospinning development is focused on the creation of composite fibers. The creation of nanofibers with a core and shell made from different materials is becoming a powerful tool for developing more custom and potentially useful nanofibers. A coaxial needle is used to dispense two immiscible liquids. At the Taylor Cone, the shell liquid pulls the inner liquid into the nascent nanofiber creating a core structure. Even more sophisticated fibers can be produced with multiple layers using a triaxial or quadaxial (tetra-axial) spinneret. There are a number of variables that can be used to control the structural and morphological properties of the electrospun nanofiber. These include: the types of polymers used, the rate of evaporation and solubility of the solvents used, the flow rates of the liquids, the distance from the Taylor Cone and the collector, the conductivity of the liquids, the needle gauge, the location of the inner needle relative to the outer needle1, the electrical voltage applied, and so on. By controlling these variables, not only can the porosity of the nanofiber be controlled but so too can the density, fiber diameter, and morphology be controlled. Electrospinning is used to produce nonwoven filters. For air applications, such as HEPA filters, electrospun nanofibers offer high filtration efficiency with limited air flow resistance. For other filtering applications, nanofiber filters provide excellent absorption of water and adsorption of chemicals such as benzene and toluene. Electrospun nanofibers are also used to produce a polymeric mesh that emulates specific biological structures. The size and porous nature of nanofiber mesh can be fabricated to emulate biostructures in terms of physical characteristics. This permits unlimited potential for wound dressing and tissue engineering applications such as vascular grafts, neural tissue, tendons and ligaments, and even bone tissues. Nanofibers offer a large surface area to volume ratio which is further augmented by the porosity of the nanofibers. Additionally, nanofibers offer tremendous versatility in drug and gene delivery applications. By controlling the fiber diameter and porosity, drugs (such as proteins, antibiotics, anti-inflammatory and anti-cancer agents) can be released at precise and optimal rates. Drug-loaded nanofibers have the potential to benefit implant methods as well as aid in postsurgical procedures that reduce infection, adhesion, and promote timelier healing.

Coaxial and multilayer electrospinning opens up additional possibilities and flexibility for drug delivery systems. By encapsulating the drug-infused solution with an outer shell, the release can be slowed tremendously at the rate of nanofiber degradation. The release rate can be tweaked further by altering the polymer concentration of the shell which affects its thickness and subsequent rate of degradation. If you're involved in any aspect of traditional or coaxial electrospinning research, it will not take long to appreciate the need for a custom spinneret. Here at ramé-hart instrument company, we take pride in offering the widest array of prebuilt and custom-made coaxial, triaxial, and quadaxial needles as well as multi-channel and side-by-side spinnerets, spinneret arrays, and accessories. If you're looking for a spinneret and can't find it on our website, chances are we can make a special order spinneret to your specifications. Contact us today to let us know how we can help you with your spinneret requirements. 1 See DIM C in this

worksheet. Note that our spinneret

products are not intended for medical applications where regulated by

FDA requirements. |

| Coupon Offer |

For a limited time only, save $35 on the

purchase of any prebuilt

coaxial,

triaxial, or

quadaxial needle. Simply use the coupon code below.  |

|

Regards,

Carl Clegg |