|

Electrospinning is a powerful technique

for producing fibers by using an electrical force to draw small diameter

threads from polymer solutions. The process is fairly simple and has

been refined extensively in the past decade or two. Electrospun fibers

are used extensively in myriad applications - from medical to

filtration, cosmetics, nonwoven textiles, and more.

While electrospinning is a suitable

process for fiber production, the usefulness of the fibers can be

greatly amplified by using different materials in a process called

coaxial electrospinning. When two immiscible liquids are supplied via

two different dispensing syringes to a coaxial spinneret, a core-shell

nanofiber can be produced.

In order to successfully make core-shell

fibers, the coaxial spinneret must exhibit a number of characteristics.

Here is the checklist:

- Excellent electrical conductivity.

Our ramé-hart prebuilt and custom coaxial needles are fabricated

from premium polished Type 304 Stainless Steel which is welded to

Luer hubs for excellent conductivity. The inner component and outer

component are sealed with a PTFE washer. However, under the washer

the two components are joined using metal-to-metal contact for

excellent conductivity throughout the entire spinneret assembly.

- Optimal connectivity. All of our

spinnerets feature the industry-standard female Luer lock interface.

Coaxial needles can be connected directly to a syringe with a male

Luer lock connection or can be connected via our

PTFE Tubing Kit. We also offer

couplings for connecting to flexible tubing - such as

Tygon. The custom coaxial needle can be configured so the two

inlets are parallel (Style C) and at any distance required (DIM E).

See worksheet

here.

ramé-hart Coaxial Needle with Luer

Lock Inlets

- Excellent concentricity. In order

to produce core-shell fibers with a uniform shell thickness, it's

critical that the inner needle is concentric to the outer. We use a

proprietary technique that ensures concentricity no matter what

gauge tubing is used. This is a standard feature on every ramé-hart

prebuilt and custom coaxial needle.

ramé-hart Coaxial Needle with

Excellent Concentricity

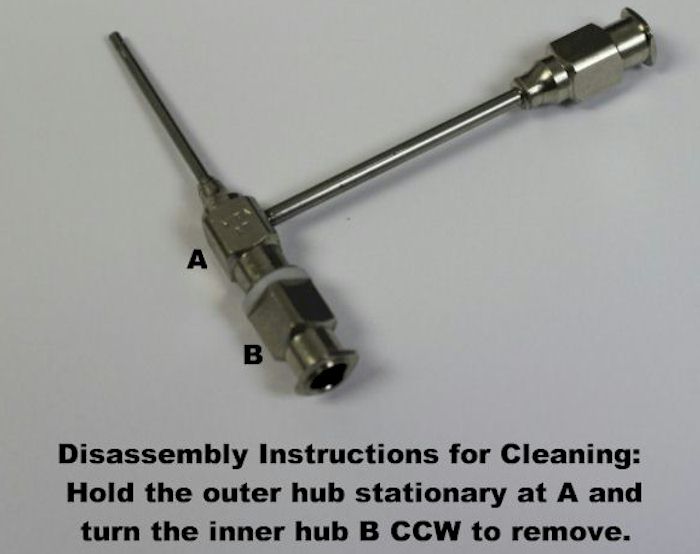

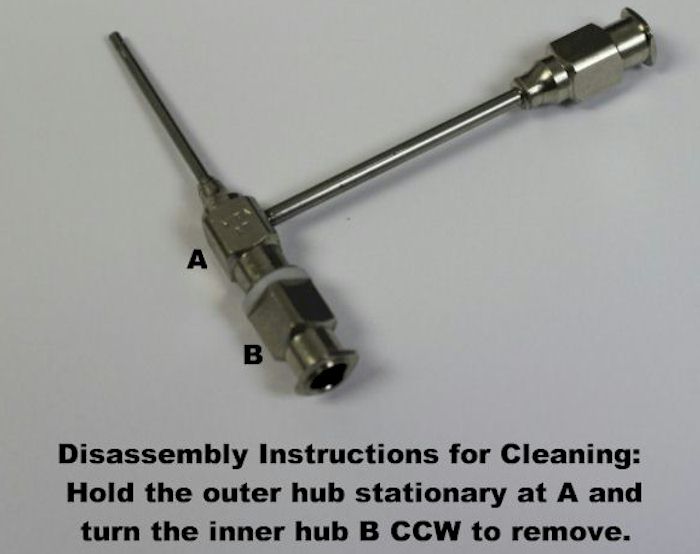

- Easy to clean. All of our prebuilt

and custom spinnerets can be disassembled for cleaning. The

image below shows how easy to take apart a ramé-hart coaxial

needle. We offer a

wrench to facilitate this as well as

cleaning wire kits and

needle files.

ramé-hart Coaxial Needle Disassembly

Instructions

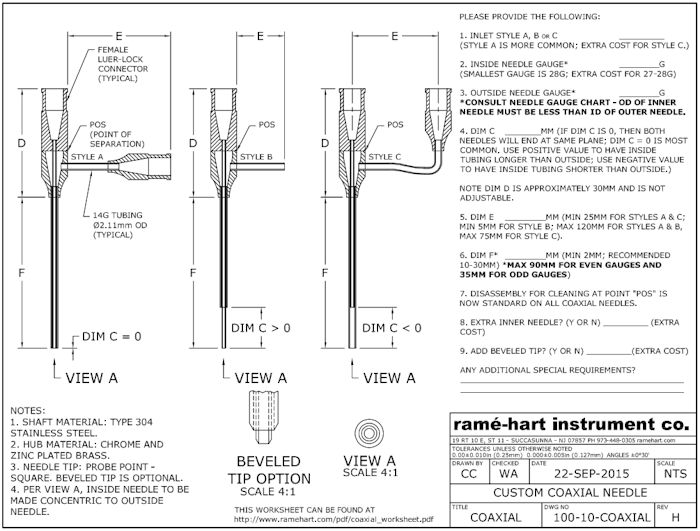

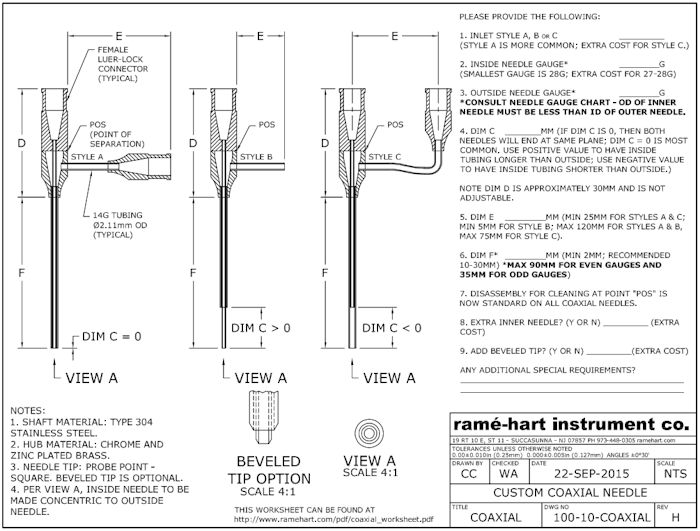

- Dimensional flexibility. While our

prebuilt coaxial needles are preconfigured for the most popular

settings, our

custom coaxial needles can be highly optimized. DIM C, for

example, allows the inner needle to be precisely positioned beyond,

inside, or flush with the outer needle as required by your unique

application. You can also control the needle length (DIM F) and side

inlet (Style A, B, C, and DIM E).

ramé-hart Custom Coaxial Needle

Worksheet (click

to enlarge)

- Long life. All ramé-hart

spinnerets are designed for hundreds of uses. In order to maximize

your investment, we offer replacement

PTFE Washers which can wear out and become compressed after many

uses. We also offer additional inner needle components as they tend

to wear out first.

- Gauge flexibility. We offer

needles from 5g to 33g. Coaxial needles can be made from sizes 5g to

28g which are all kept in stock. Even gauges are available in longer

lengths than odd. For inside and outside diameter dimensions, check

out our

needle chart.

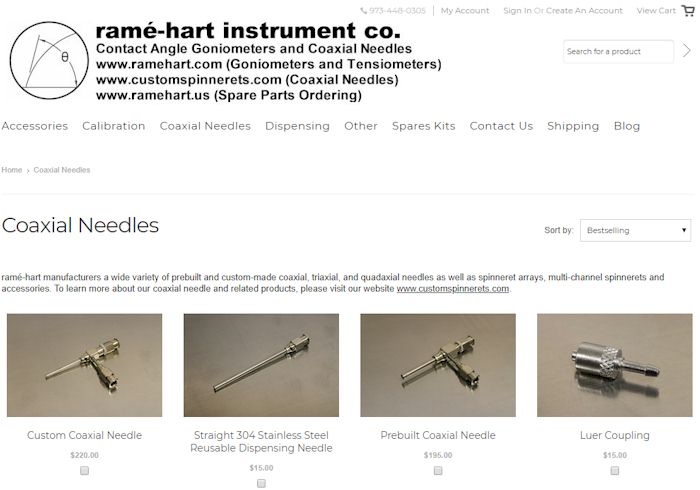

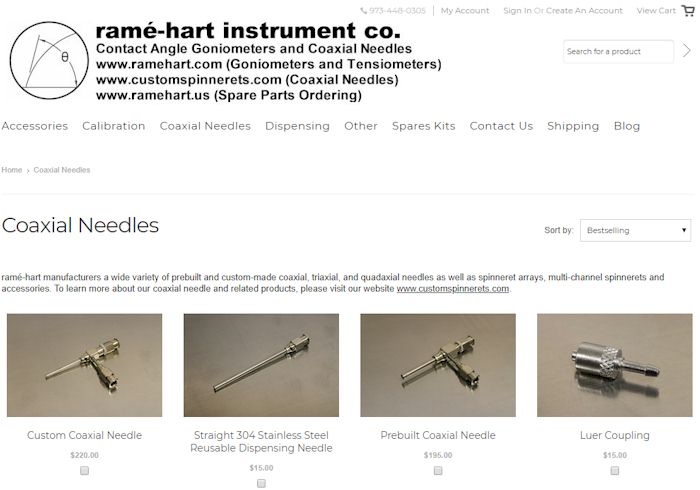

- Ease of ordering. We've tried to

make it as easy and flexible as possible to order a custom

spinneret. To get started with a coaxial spinneret, start on this

page. We accept credit card, bank wire, and other forms of

payment. We can ship to any address on the planet earth.

Online Ordering for ramé-hart

Coaxial Needles (click

here

to go to the store)

- Availability. We keep all prebuilt

spinnerets in stock and ready for immediate shipment. Custom

spinnerets are made and shipped within one week. We even offer an

expedite option if you're in a rush.

- Quality. Each spinneret product is

flushed and tested for leaks and flow. Each dimension and feature is

also inspected prior to shipment.

- Warranty. We warranty all

spinneret products for one year. Fewer than 1% of our spinnerets are

returned for warranty repair or replacement.

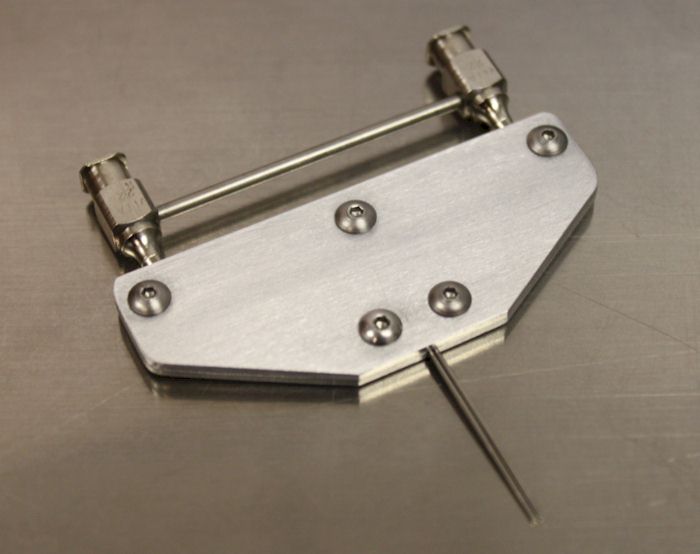

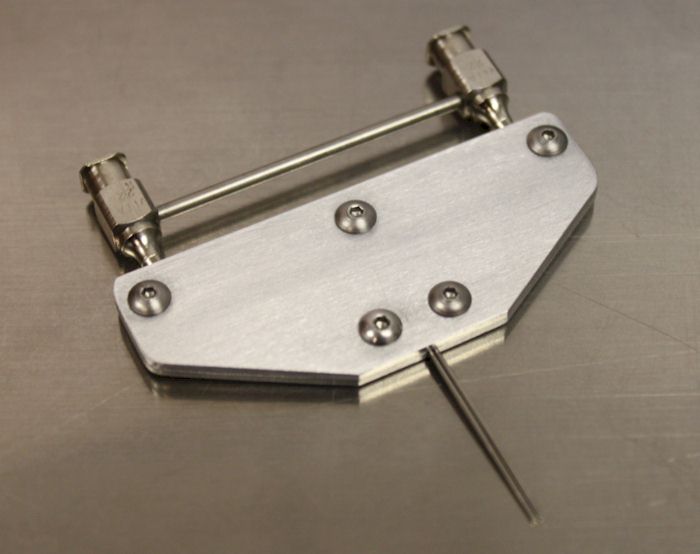

- More than coaxial. We also offer

prebuilt and custom

triaxial and

quadaxial needles as well as

multi-channel and

side-by-side spinnerets and

spinneret arrays.

ramé-hart Side-by-side Spinneret

- Beveled Tip Option. There are some

applications which work best if the tip of the needle is beveled.

This option is available on custom coaxial, triaxial, and quadaxial

needles.

ramé-hart Custom Triaxial Needle

with Optional Beveled Tip

- Imitated but peerless. Imitation

is the ultimate form of flattery. There are a couple of vendors in

China and India who have attempted to copy our proprietary coaxial

needle design but their products are inferior on every point above.

And while we admire the do-it-yourselfers, many have turned to us

after they realized how challenging it is to make a quality coaxial

spinneret that actually works.

- Volume. Whether you need one, two

or 100 coaxial needles, we are setup to provide you with your

spinneret needs. For large volume orders, please

contact us

for a discounted price and lead time.

Whatever your application is, we can

provide the spinneret and tubing parts. Please feel free to

contact us

if you have a special spinneret application that does not conform to our

prebuilt or custom designs. We make all types of custom

and special-order spinnerets to meet your exacting specifications.

|