|

November 2021 |

| The art and science of mask making |

|

At the beginning of the pandemic, it

became obvious that widespread use of face masks can contribute to

the slowing of the spread of the virus. Mask efficacy, however,

varies widely depending on design and materials used. In the past

year, a lot of research has led to better understanding what works

and why. Electrospun nanofibers are excellent at capturing droplets of virus-laden aerosol. On a related note, ramé-hart is the world-leader in the production of custom spinnerets used for coaxial electrospinning and electrospraying.1 With face masks made from nanofibers, capillary forces have been seen to cause nanofibers to bond together after the aerosol is captured. This bond persists even after the droplet evaporates.

By using hydrophobic fibers, the coalescing is minimized. Moreover, it's suggested that coaxial nanofibers may lead to an optimal material in which the inner core material is strong and moderately elastic while the outer sheath material is hydrophobic and antiviral. A better understanding of how nanofibers behave with aerosol can result in improvements to masks design and provide a better understanding of their effective lifespan. During cold weather, more droplets are ejected during breathing and talking and this leads to a reduced period of efficacy. Another consideration is whether the mask material is able to adsorb viral droplets as opposed to blocking them. Researchers at Stony Brook University conducted a study using spray simulation to better understand the trapping mechanism.2 Wetting properties were measured using contact angle with artificial saliva. X-ray fluorescence spectroscopy was used to measure how many droplets were passing through the material.

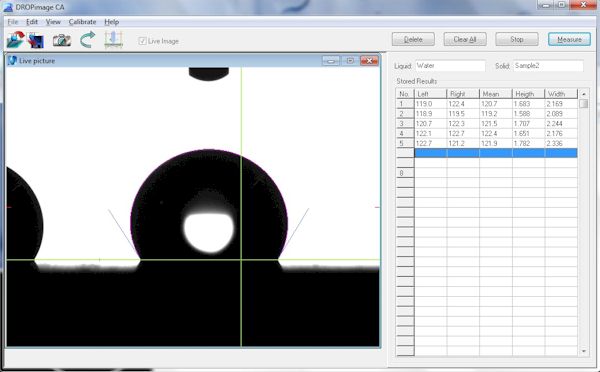

For maximum blocking capabilities, nonwoven materials are frequently used for the outer shell material because of their hydrophobic properties. A ramé-hart Model 190 with DROPimage CA software is used to measure the wetting properties of a nonwoven polypropylene surface on a sample mask. Note that the inside surface of this mask is made of a fibrous nonwoven material designed to absorb liquids. Thus the outside of the mask repels droplets while the inside absorbs them. By quantifying the efficacy of different mask materials, researchers are finding novel ways to improve mask designs. We contribute to this research by building contact angle goniometers for measuring wetting properties as well as custom spinnerets used for nanofiber production and related research. Notes 1 Learn more about

ramé-hart custom spinnerets at |

| We welcome Mike Schroeder |

|

This month we hired a new machinist, Mike

Schroeder - not to replace anyone but to add additional capacity to our

shop. Mike has over 40 years of machining experience and brings with him

a wide variety of shop skills that we will put to use building

premium instruments and custom spinnerets. Welcome, Mike. |

|

Regards,

Carl Clegg |