|

December 2021 |

| Nanofinishes |

|

There is no material that in solid

smooth form will produce a contact angle over about 120°. That

statement is also true for surfaces that have a roughness so long as

the drop remains in a Wenzel state.1 PTFE is an example

of a material that is naturally hydrophobic with a contact angle

over 100°. It can be as high as 107°.

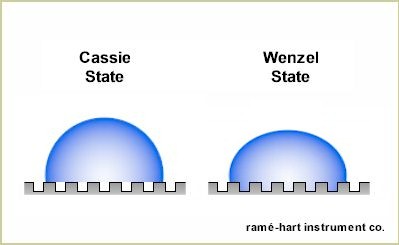

In order to achieve higher contact angles, the surface must exhibit a roughness and the drop must be in a Cassie state - that is, sitting on top of the nanoscopic pillars with pockets of air in the nooks and crannies underneath the drop (as shown in the graphic above). In the Cassie state, the contact angle can exceed 150° which is referred to as ultrahydrophobic.2 The lotus leaf is one of a number of surfaces found in nature that is ultrahydrophobic. The extremely high contact angle of the lotus leaf (up to 170°) is achievable as a result of a hierarchal structure. The surface is covered with papillae that are 10-15 µm in diameter and 10-20 µm tall. These features are then coated with a self-regenerating and hydrophobic epicuticular wax. Together the natural topology and the waxy surfaces work together to promote a Cassie state that exhibits a very low contact angle hysteresis, a low roll-off angle, an unusually high contact angle, and an amazing self-cleaning property. Scientists have expended untold energy trying to figure out how to best replicate the lotus leaf using a variety of methods. Today, we will take a look at five common nanofinishing methods for producing ultrahydrophobic surfaces. Chemical vapor deposition (or CVD) is a method for forming thin films through a chemical reaction on a heated substrate surface using gases that contain the desired material to be deposited. It's frequently used by the chip makers to produce thin films. Nanoscopic topologies can be produced using this method which, through optimization, can lead to a variety of ultrahydrophobic surfaces with a variety of wetting behaviors in the Cassie regime. Sol-gel processing starts with a liquid which passes through hydrolysis condensation and gelation to become a wet gel. The gel can be spin coated or evaporated to produce an xerogel film. Textiles can be treated using sol-gel technology to decrease wetting behavior and increase water repellency. Nanoparticles can be added to enhance hydrophobicity. Layer-by-layer (LBL) deposition can be used on polymer, glass, and metal surfaces. One method produces a composite coating that is spin-assembled layer-by-layer. Silica nanoparticles are added and the coating is applied to type 316 stainless steel to produce a water contact angle over 150° with a roll-off angle of 6°. Graft polymerization is yet another method for producing ultrahydrophobic surfaces. Researchers in Canada are developing methods that will make naturally hydrophilic biodegradable cellulose-based plastic ultrahydrophobic.3 Modifications to the material surface include roughening the surface and then adding a surface coating with microscale structural features. While several methods can accomplish this, polymer grafting - which is done by promoting chemical reactions - is particularly effective. Using graft polymerization, cellulose samples with a natural contact angle of only 10° were made ultrahydrophobic with water contact angle readings in excess of 155°.

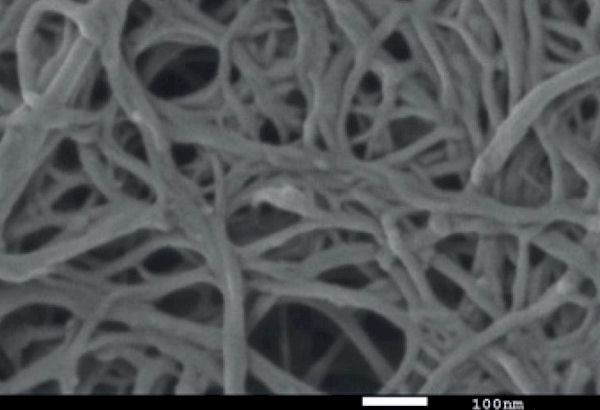

Lastly, surface roughness can be enhanced through electrospinning. A compelling advantage to this method is the wide array of polymeric materials that can be electrospun. Even more exciting is coaxial electrospinning in which the core and sheath materials can be optimized for a particular property. For example, the core material can be made strong and conductive while the sheath material might be made from biofriendly and hydrophobic polymers.4 This ability to mix and match inner and outer nanofiber materials produces a nearly unlimited array of design parameters. Another advantage to electrospinning is amazing control over the parameters used to produce electrospun ultrahydrophobic surfaces. In the case of electrospun PVDF mats, for example, polymeric concentration, flow rate, nanoparticles loading, ratio of solvents, spinning distance and spinneret size can all affect the wetting properties of the resulting fibrous mats. In the case of coaxial electrospinning, the configuration of the spinneret can have a significant impact on the properties of the resulting nanofibers.5 Notes 1 For a review of Wenzel

and Cassie states, see this

definition. |

| Season's Greetings |

|

Despite the pandemic, the chip shortage,

inflation, and supply chain challenges, we've had a pretty good year. In fact, 2021

is our 60th anniversary. ramé-hart was born in 1961 in Mountain Lakes,

New Jersey, just 10 miles east of our current location. For sixty years,

we've maintained an eye for quality manufacturing, innovative solutions,

and an unrelenting quest to provide excellent customer service. Thank

you for your business. It's an honor to serve you. We hope that you and your team and family have a festive and safe holiday season and may you enjoy a healthy and happy New Year 2022 as well! |

|

Regards,

Carl Clegg |