|

November 2022 |

| Tunable Wetting Behavior - Part Two |

|

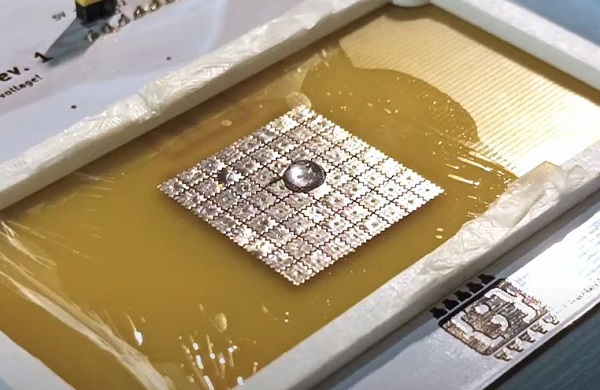

Last month we introduced the idea of a responsive smart surface - that is, a surface which permits the wetting behavior to be adjusted or fine-tuned using external stimuli and without permanently modifying the surface. We covered several stimuli: magnets, silanization and desilanization, polymer brushes that are controlled by different solvents, and tunable micro-wrinkles. Another potentially effective stimulus is an electrical field. The phenomenon of electrowetting is based on the principle of electrocapillarity which was first explained and demonstrated by a Frenchman named Gabriel Lippmann in 1873. It wasn't until the 1990s that a thin insulating layer is proposed in order to prevent electrolysis. In a standard electrowetting setup for microfluidic manipulation, electrodes are mounted to a surface. These are then coated with a dielectric layer and then a very thin hydrophobic surface. When a drop is deposited on the surface and voltage is applied to the electrodes under the drop, the surface tension of a drop is reduced which leads to greater wetting and subsequently a lower contact angle when energized. By creating an array of electrodes, it's possible to build a lab-on-a-chip on which a drop can be moved around simply by changing which electrodes are energized.1 Another class of smart surfaces respond to changes in temperature. Thermoresponsive polymers like Poly-isopropylacrylamide (PNIPAAm) are used to fabricate surfaces which have wetting behavior that can be controlled by the temperature.2 When the temperature is below the lower critical solution temperature (LCST) which is 32°, the intermolecular hydrogen bonding becomes weak and the result is hydrophilic behavior. At higher temperatures, the strong hydrogen bonding promotes hydrophobic behavior. If roughness is added, a thermoresponsive surface can have a wide spectrum of wetting behavior, from complete wetting with a contact angle of 0° to superhydrophobic with a contact angle in the 150° neighborhood. A smart photoresponsive surface exhibits a change in wetting properties depending on what light or lack of light is shed on it.3 Surfaces made from titanium dioxide (TiO2), for example, have been hydrophilic by applying UV irradiation. Under UV illumination, the thin film of titanium dioxide transitions from a Ti4 state to a Ti3 state making it hydrophilic. When the surface is placed in darkness, the state reverses and the surface becomes hydrophobic once again. In short, smart responsive surfaces with tunable wettability driven by various external stimuli prove to be useful candidates in a variety of novel applications where continuous and reversible surface wetting is advantageous. These surfaces use the extra energy gained from the external stimulus to change their wetting behavior as needed. Surface wetting properties can be changed from hydrophobic to hydrophilic on smooth surfaces and from superhydrophilic to superhydrophobic on roughened or patterned surfaces. Because each technique has few advantages and disadvantages over others, there is a wide array of options available to researchers. There may be some limitations where scientific understanding is not completely clear and that is currently the subject of additional research. Notes |

| Tech Tip: Two Ways to Measure Contact Angle |

|

This month we are going to address the

question: What is the best way to measure contact angle using

ramé-hart DROPimage Advanced? There are two common ways: the Contact

Angle Tool and a methods-based experiment.

First, let's address some of the advantages of using the Contact Angle Tool:

In general, the Contact Angle Tool should be your go-to tool for most contact angle measurements. However, if you are doing any type of time dependent study or taking dynamic measurements, then a methods-based experiment may be the way to go. Here are the key advantages of the methods-based method:

To conclude, use the Contact Angle Tool for most applications and when you want to measure the surface energy. If you are doing a dynamic experiment including those that integrate automatic tilting or dispensing, consider creating a methods-based experiment. Notes |

|

Regards,

Carl Clegg |