|

Visit our website at

www.customspinnerets.com

|

|

Coaxial Electrospinning Revisited |

|

Coaxial electrospinning is a specialized

form of electrospinning, a technique used to create nanofibers with

diameters ranging from a few nanometers to several micrometers. In coaxial electrospinning, two or more solutions are simultaneously electrospun from a single coaxial spinneret or nozzle, with the inner solution flowing through the center of the outer solution. The solutions are charged with opposite polarity, and as they emerge from the nozzle, the electrostatic forces cause the solutions to spin and form a cone shape. As the spinning cone becomes unstable, it ejects a jet of fluid that travels toward a collector. During this process, the solvent evaporates and the polymer or other materials in the solution solidify, forming nanofibers with a core-shell structure. Coaxial electrospinning is used to produce nanofibers with a variety of applications in areas such as tissue engineering, drug delivery, and sensors. The core-shell structure of the fibers allows for the encapsulation of different materials within the core, such as drugs or proteins, which can be released in a controlled manner over time.

Let's first take a look at tissue engineering, where coaxial electrospinning is used to create nanofibers that mimic the extracellular matrix (ECM) of natural tissues.1 The core-shell structure of the fibers produced by coaxial electrospinning allows for the encapsulation of different bioactive agents, such as growth factors, peptides, or cells, which can be delivered in a controlled manner to promote tissue regeneration. One application of coaxial electrospinning in tissue engineering is the development of scaffolds for tissue regeneration. The nanofibers produced by coaxial electrospinning can be tailored to mimic the mechanical properties and architecture of natural tissues, such as skin, bone, or cartilage. The core-shell structure of the fibers can be used to encapsulate different types of cells or growth factors, promoting cell proliferation and differentiation and guiding the formation of new tissue. Another application of coaxial electrospinning in tissue engineering is the production of drug delivery systems. The nanofibers produced by coaxial electrospinning can be used to encapsulate drugs or other bioactive agents, which can be released in a controlled manner over time. This allows for targeted and sustained drug delivery to specific areas of the body, such as the site of an injury or disease.2 Coaxial electrospinning is also a promising technique for the development of sensors due to the ability to produce nanofibers with tailored structures and properties. The core-shell structure of the nanofibers produced by coaxial electrospinning allows for the encapsulation of sensing materials, which can enhance the sensitivity and selectivity of the sensors. One application of coaxial electrospinning in sensor development is the production of gas sensors.3 The nanofibers produced by coaxial electrospinning can be tailored to encapsulate sensing materials, such as metal oxides, which can be used to detect gases such as carbon monoxide, nitrogen dioxide, and hydrogen. The high surface area and porosity of the nanofibers enhance the sensitivity of the sensors, making them suitable for use in air quality monitoring, environmental monitoring, and gas leak detection. Another application of coaxial electrospinning in sensor development is the production of biosensors. The core-shell structure of the nanofibers produced by coaxial electrospinning can be used to encapsulate sensing materials, such as enzymes or antibodies, which can be used to detect specific biomolecules. The nanofibers can also be functionalized with different surface chemistries, enhancing the selectivity of the sensors. These biosensors have potential applications in healthcare, food safety, and environmental monitoring. Coaxial electrospinning is a versatile technique that has numerous applications in various fields, including tissue engineering, drug delivery, sensors, and energy storage. Here are some of the less common applications of coaxial electrospinning: 1. Optical fibers: Coaxial electrospinning has been used to produce optical fibers with a core-shell structure, where the core is made of a high-refractive index material, and the shell is made of a low-refractive index material. These fibers can be used in applications such as telecommunications, sensors, and biomedical imaging.4 2. Water treatment: Coaxial electrospinning has been used to produce nanofibers with photocatalytic properties, which can be used for water treatment and desalination.5 The nanofibers can be coated with a photocatalytic material, such as titanium dioxide, which can decompose organic pollutants in water under UV irradiation. 3. Catalysis: Coaxial electrospinning has been used to produce nanofibers with catalytic properties. The nanofibers can be coated with a catalytic material, such as metal nanoparticles, which can be used in applications such as hydrogen production, organic synthesis, and environmental remediation. 4. Sound absorption: Coaxial electrospinning has been used to produce nanofibers with sound-absorbing properties.6 The nanofibers can be coated with a sound-absorbing material, such as polyurethane foam, which can be used in applications such as building acoustics, noise reduction, and automotive insulation. In short, coaxial electrospinning is a versatile technique not only for tissue engineering, drug delivery, and sensor development, but a variety of additional applications which are being developed and even more that have yet to be discovered. ramé-hart instrument company is passionately dedicated to producing the world's finest and most customized coaxial spinnerets used for every conceivable coaxial electrospinning application. Contact us today or visit our website www.customspinnerets.com if you're involved in any level of coaxial electrospinning. We are here to help you succeed. Notes 2 Electrospun poly(methyl methacrylate)/polycaprolactone (PMMA/PCL) core-sheath fibers have shown great potential for drug delivery applications due to their unique properties, such as high surface area-to-volume ratio, tunable morphology, and biocompatibility. Read more in this paper from another of our customers: http://dx.doi.org/10.1007/s10853-018-03261-2 3 Coaxial electrospinning can be used to produce heterojunction SnO2/Au-doped In2O3 core-shell nanofibers for acetone gas sensors. The inner needle is used to electrospin a solution of SnO2 nanoparticles, while the outer needle is used to electrospin a solution of Au-doped In2O3 nanoparticles. The two materials are spun together to form a core-shell structure, where the SnO2 nanoparticles form the core and the Au-doped In2O3 nanoparticles form the shell. The resulting heterojunction structure provides enhanced sensing properties compared to single-component sensors. The SnO2/Au-doped In2O3 heterojunction creates a Schottky barrier, which leads to improved gas sensing performance. The SnO2 acts as a sensing material, while the Au-doped In2O3 acts as a transducer material, converting the chemical reaction into an electrical signal. The resulting core-shell nanofibers have a high surface area-to-volume ratio and a porous structure, which provides a large active surface area for gas sensing. The nanofibers also have excellent mechanical properties and high thermal stability, which makes them suitable for use in harsh environments. The use of coaxial electrospinning to produce heterojunction SnO2/Au-doped In2O3 core-shell nanofibers for acetone gas sensors is a promising approach. Read more in this article: https://doi.org/10.1016/j.snb.2017.06.077 4 Another of our customers using a ramé-hart Prebuilt Coaxial Needle and also a Model 250 Goniometer performed proof-of-concept studies to show that coaxially electrospinning can be successfully employed to product thermochromatic nanofibers. Read more here: https://doi.org/10.3390/polym12040842 5 A novel thin-film composite membrane is fabricated from a coaxial electrospun nanofiber which exhibits high porosity, high hydrophilicity, and is suitable for desalination applications. Read more here: https://doi.org/10.1016/j.desal.2018.07.025 6 A ramé-hart Custom Coaxial Needle is used to produce nanofibers with a poly(caprolactone) (PCL) polymer sheath and poly(ethylene glycol) (PEG) fluids in the core which are in turn used to fabricate sound dampening nonwoven mats. Read more here: https://doi.org/10.1021/acsapm.9b00352 |

|

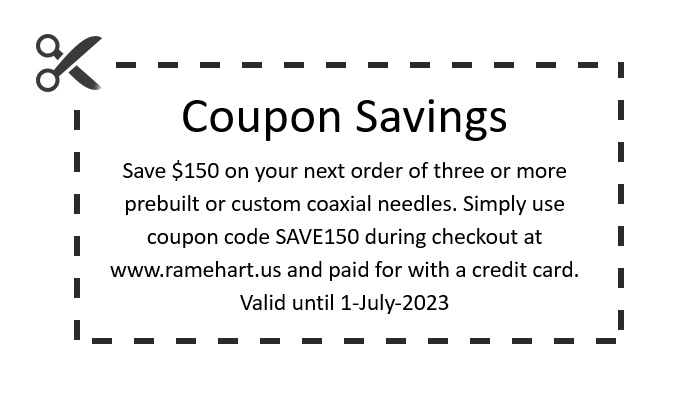

Promo Codes for Saving |

|

If you made it this far, we'd like to

treat you to some savings. Use either of the following coupons on your next

spinneret order.

|

|

Regards,

Carl Clegg |