|

Visit our website at

www.customspinnerets.com

|

|

Coaxial Bioprinting - An Overview |

|

In our last newsletter, we revisited

coaxial electrospinning, the most popular use for our prebuilt and

custom coaxial needles. The second most popular application is

bioprinting. Bioprinting is an advancing technology that enables the

precise design and production of tissues in different biological systems

and organs. Within this field, coaxial extrusion bioprinting has emerged

as a promising branch, offering enhanced engineering versatility. By

enabling the concentric deposition of biomaterials, coaxial bioprinting

facilitates the fabrication of intricate tissue constructs. What

initially started with the creation of simple, tubular vasculature has

now evolved significantly, incorporating complex cell compositions,

self-assembly, ECM patterning, controlled release, and multi-material

gradient profiles. In this article, we aim to provide a concise overview of the history of coaxial printing and introduce the key engineering components involved. Subsequently, we delve into the recent advancements and untapped potential of coaxial bioprinting in specific organs or biological systems, highlighting how it enables the development of tissue constructs. Ultimately, we conclude that this rapidly evolving technology will make significant contributions to the fields of in vitro modeling, pharmaceutical development, and clinical regenerative medicine. The history of coaxial bioprinting can be traced back to the development of conventional bioprinting techniques. The concept of bioprinting itself gained attention in the early 2000s when researchers began exploring the idea of using 3D printing technology to create living tissues and organs. However, early bioprinting methods faced limitations in terms of their ability to accurately deposit multiple biomaterials and create intricate structures. Coaxial extrusion bioprinting, the branch that focuses on coaxial deposition of biomaterials, was introduced as a solution to overcome these limitations. It enabled the simultaneous extrusion of two or more materials through a coaxial nozzle, resulting in the deposition of concentric layers. The early development of coaxial bioprinting primarily focused on establishing the technical feasibility of coaxial deposition and optimizing the printing parameters. Researchers worked on refining the nozzle design, biomaterial formulations, and printing strategies to achieve precise control over the deposited materials. In that same period, ramé-hart instrument co., our company, made significant strides in the development and enhancement of a system that has become widely adopted by prominent bioprinting entities. This system empowers researchers to effortlessly design a personalized coaxial needle using a straightforward worksheet. Subsequently, based on the provided specifications, a tailor-made coaxial nozzle can be fabricated in a remarkably short timeframe of one week or even less. Over time, coaxial bioprinting expanded its capabilities beyond the simple deposition of biomaterials. Researchers started integrating additional functionalities, such as the incorporation of cells within the deposited materials, to create more complex tissue constructs. Furthermore, advancements in coaxial bioprinting techniques enabled the introduction of other features, including the ability to control release profiles of bioactive compounds, the creation of multi-material gradient profiles, and the patterning of extracellular matrix (ECM) components. These developments opened up new possibilities for mimicking the intricate structures and functions of native tissues. As research and development in coaxial bioprinting progressed, the technology demonstrated its potential for applications in various organ systems, including but not limited to vascular networks, cardiac tissues, neural tissues, and musculoskeletal structures. The ability to create tissue constructs with higher complexity and functionality became a focal point of exploration. Coaxial bioprinting involves several key engineering components that are instrumental in achieving precise and controlled deposition of biomaterials. These components include: Coaxial Nozzle: The coaxial nozzle is a critical component that enables the simultaneous and concentric extrusion of multiple biomaterials. It comprises both an outer and an inner nozzle, facilitating the coaxial flow of materials. The design and dimensions of the coaxial nozzle hold significant importance as they directly influence the diameter and thickness of the printed constructs. At the forefront of this field, ramé-hart has established itself as the global leader in fabricating custom coaxial nozzles utilized in bioprinting applications. In addition to offering template-based custom coaxial needles, ramé-hart also specializes in building tailor-made coaxial nozzles that cater to specific requirements, including arrays, multi-channel nozzles, and various other special configurations meticulously crafted to meet the precise specifications of the customers.

Syringe Pump System: Coaxial bioprinting requires a syringe pump system to precisely control the flow rates of the outer and inner materials. The syringe pumps provide the necessary pressure and regulate the extrusion speed of the biomaterials, ensuring a consistent and controlled deposition. Biomaterials: The choice of biomaterials is an essential aspect of coaxial bioprinting. Typically, a coaxial bioprinting system employs two or more biomaterials with distinct properties, such as viscosity, mechanical strength, and bioactivity. The outer material often serves as a support or sacrificial layer, while the inner material contains cells or bioactive components. Crosslinking or Solidification Methods: After deposition, the biomaterials in coaxial bioprinting need to be crosslinked or solidified to maintain their shape and stability. Various techniques can be employed for this purpose, such as exposure to light (e.g., UV or visible light), temperature changes, or the addition of crosslinking agents. The appropriate method is chosen based on the specific properties of the biomaterials used. Control System and Software: Coaxial bioprinting systems are typically equipped with a control system and specialized software. This allows researchers to precisely adjust and monitor parameters such as extrusion rates, layer thickness, and nozzle movement. The software often provides a user-friendly interface for designing the desired coaxial patterns and controlling the printing process. Coaxial bioprinting has witnessed remarkable advancements in recent years, pushing the boundaries of tissue engineering and regenerative medicine. Researchers have made significant progress in refining the coaxial deposition process, enabling greater precision and control over the printed structures. Recent developments have focused on incorporating more complex functionalities into the printed constructs, such as integrating multiple cell types, creating vascular networks, and accurately patterning extracellular matrix components. Moreover, the integration of advanced technologies, including cellular self-assembly and microfluidics, has expanded the capabilities of coaxial bioprinting, allowing for the creation of highly intricate and functional tissue models. These advancements in coaxial bioprinting hold tremendous promise for applications in drug screening, personalized medicine, and the development of complex organ-like structures for transplantation. Today, coaxial bioprinting continues to evolve, with ongoing research efforts aimed at improving printing resolution, expanding the range of printable biomaterials, and integrating advanced techniques like bioprinting with cellular self-assembly. The technology holds promise for advancing regenerative medicine, in vitro modeling, and pharmaceutical development, as it enables the precise engineering of tissues with unprecedented control and sophistication. |

|

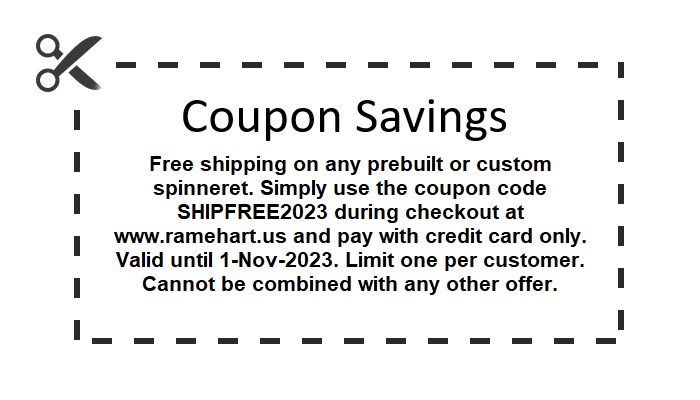

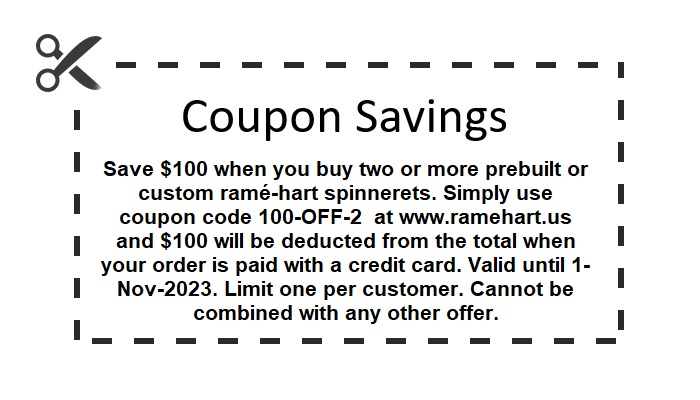

Promo Codes for Saving |

|

If you made it this far, we'd like to

treat you to some savings. Use either of the following coupons on your next

spinneret order.

|

|

Regards,

Carl Clegg |