|

Visit our website at

www.customspinnerets.com

|

|

A Sampling of Coaxial Spinneret Applications |

|

We are motivated to better understand the

variety of applications for which our spinneret products are being used.

We marvel at the ingenious research which has produced so many solutions

to critical life-sustaining problems. We are seeing an array of new

biomedical applications that provide controlled drug release,

nanosensors, and bio-marking. In addition, there are innumerable

industrial and commercial applications that benefit from optimized

core/sheath electrospun fibers. In this edition of The Spinneret, we

will share with you eight applications for which our coaxial needle

product is being used today to solve numerous vexing problems. If you'd

like to share an application for a future newsletter. Please

reach

out to us and share your paper or research with us. We'd love to

hear from you.

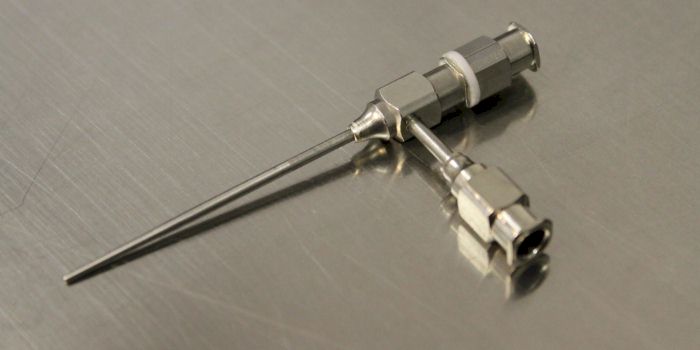

Here are the eight: - A Cornell student employs a ramé-hart coaxial spinneret to fabricate a bioactive membrane for glucose sensing. Polylactic acid (PLA) and polyethylene glycol (PEG) are coaxially electrospun into a nonwoven, nanofibrous membrane with a core/sheath fiber structure using a ramé-hart Prebuilt 22g/18g Coaxial Needle.1 - Researchers at Kansas State University use a ramé-hart Custom Triaxial Needle (22g/16g/12g) to blow spin core/shell fibers that consist of a monolithic hydrophobic polycaprolactone (PCL) shell and a hydrophilic polyvinylpyrrolidone (PVP) core.2 The goal is to control drug release by improving cell proliferation through the optimization of surface wettability, porosity, and roughness. Blow spinning involves ejecting the core solution through the inner needle, the shell solution through the middle flow, and releasing compressed air through the outer flow of the spinneret. - At the Naval Research Lab (which incidentally is the birthplace of the ramé-hart goniometer3), a ramé-hart Custom Coaxial Needle (22g/12g) is used to electrospin core/sheath fibers that exhibit amazing mechanical damping properties.4 The sheath component is polycaprolactone (PCL) while the core is a liquid made up of polyethylene glycol (PEG) and SiO2 particles. The damping properties are adjustable by changing the viscosity of the core PEG fluid. In addition, nonwoven mats made from these fibers exhibit tunable sound attenuation. - At the University of Rhode Island, researchers are using a ramé-hart Custom Coaxial Needle (24g/15g) to fabricate via coaxial electrospinning a microfibrous biomaterial with encapsulated nanosensors which are used to monitor wirelessly a wound site and prevent infection. This technology promotes the development of smart wound dressings which feature various layers - e.g., layers with antibiotics, growth factors, and now a layer for monitoring biomarkers.5 - Coaxial dielectric elastomer fibers are electrospun using a ramé-hart Custom Coaxial Needle at the University of Wisconsin-Milwaukee.6 A variety of processing parameters are considered which can greatly affect and control the nature of the resulting fibers. - Chemical sensing, bio-marking, and photon sensing are a few applications that could benefit from electrohydrodynamically co-casted light-emitting fibers.7 Researchers in California use a ramé-hart (20g/16g) Coaxial Needle to produce the core/sheath fibers. Electrohydrodynamic co-casting involves applying a positive electrical charge to the spinneret while applying a negative electrical charge on the collector. - In Sweden, researchers use ramé-hart coaxial needles to fabricate scaffold structure with viable stem cells via 3D bioprinting which are used to repair bony craniomaxillofacial defects.8 While several sizes are tested, the 22g/16g proves to be the most suitable. - In a similar vein, Canadian researchers have developed coaxial electrospun scaffolds that have embedded proteins which promote angiogenic stability during wound healing.9 This development can greatly improve skin healing for diabetic patients as well as elderly and immobile patients. A ramé-hart Prebuilt Coaxial Needle (28g/22g) was used to produce core/shell fibers for these scaffolds. Many other applications are being developed that rely on the powerful core/sheath composite fiber design in which one or more encapsulated functional materials can be electrospun using a coaxial spinneret. If you are working on coaxial electrospinning projects, please feel free to check out our Prebuilt and Custom Coaxial Needle products. And if you need something special, please contact us. Special orders are our specialty. Notes |

|

Promo Codes for Saving |

|

If you made it this far, we'd like to

treat you to some savings. Use either of the following coupons on your next

spinneret order.

Fine print: Limit one coupon code per

order. Limit one use per customer. To receive the discount, order must

be placed online at www.ramehart.us

and paid for with a credit card. Enter the coupon code during checkout.

All coupon codes above expire on 1-May-2023. |

|

Regards,

Carl Clegg |