|

July

2024 |

| What are Pickering Emulsions? |

|

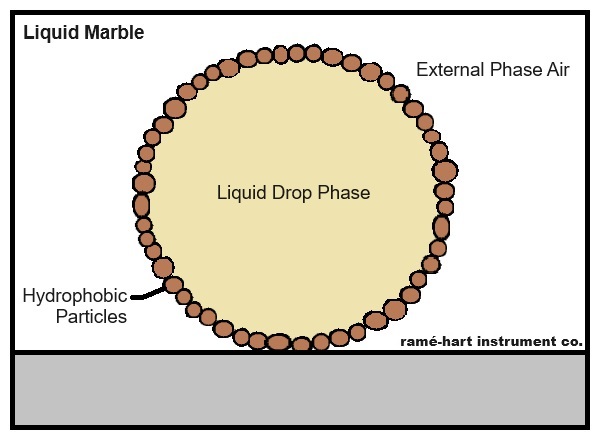

Last month we discussed liquid marbles. A liquid marble is a liquid droplet coated with a layer of hydrophobic particles that form a non-wetting surface around the drop forming a ball which behaves like a squishy solid.

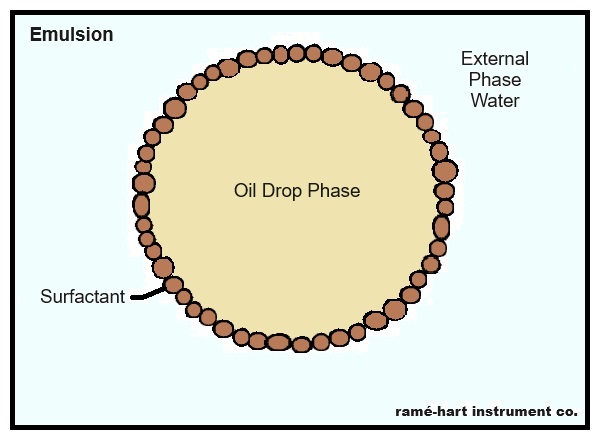

Similar to a liquid drop, an emulsion is a mixture of two immiscible liquids where one liquid is dispersed in the form of small droplets within the other. This mixture is typically stabilized by surfactants to prevent the droplets from coalescing.

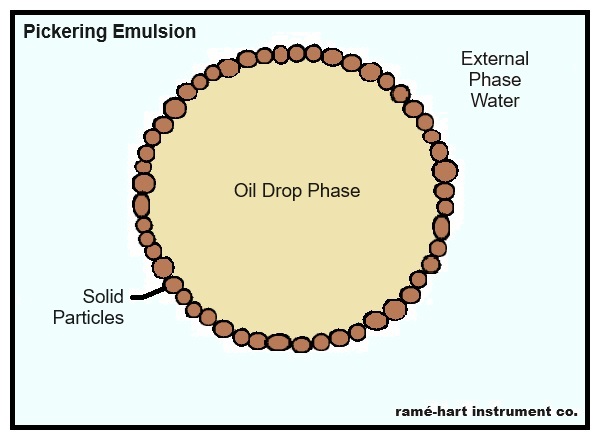

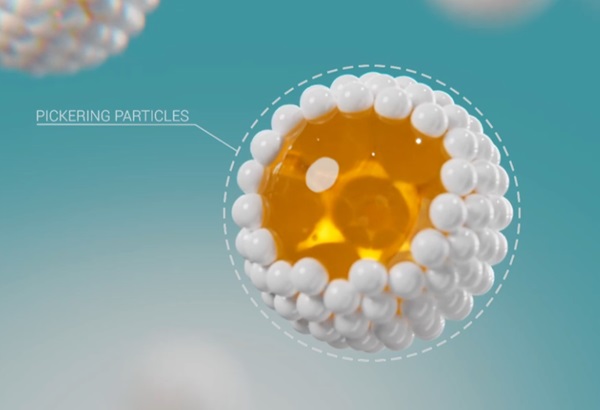

Our focus today, however, is on the Pickering emulsion, a type of emulsion stabilized by solid particles that adsorb onto the interface between the two immiscible liquids such as oil and water, creating a barrier that prevents the droplets from coalescing. Unlike traditional emulsions stabilized by surfactants, the solid particles in Pickering emulsions provide mechanical stability, resulting in a more robust and long-lasting mixture.

The Pickering emulsion is named after the British chemist S.U. Pickering who, in 1907, published his seminal paper "Emulsions" in the Journal of the Chemical Society. This paper is considered a landmark study in the field of colloid chemistry. Pickering investigated the stabilization of emulsions using solid particles, rather than traditional surfactants. He observed that fine solid particles adsorbed onto the interface between the immiscible liquid phases, forming a barrier that prevented droplet coalescence. Through experimental studies, he demonstrated that these particles, such as colloidal silica or clays, effectively stabilized the emulsion. Pickering's findings highlighted a novel mechanism of emulsion stabilization, paving the way for new research in colloid and interface science. His work fundamentally shifted the understanding of how emulsions can be stabilized, leading to the concept now known as Pickering emulsions. Pickering emulsions are also sometimes called Ramsden emulsions in honor of the earlier English biochemist, Walter Ramsden, who observed similar phenomena in 1903 but did not receive as much recognition as S.U. Pickering. While Pickering's work in 1907 provided a more comprehensive understanding of solid-stabilized emulsions, Ramsden's observations laid the groundwork for this concept, leading to the alternate terminology. It should be pointed out that while Ramsden did describe the phenomenon of particles accumulating at the surface of solutions and suspensions, he did not explore very deeply the concept of emulsions stabilized by solid particles. Thus, Pickering deserves most of the credit for discovering and understanding what we call today Pickering emulsions. It's also worth noting that the optimal contact angle for Pickering particles in a Pickering emulsion is typically around 90°, but can effectively range from 70° to 110°. This range ensures that the particles are sufficiently wetted by both phases to anchor firmly at the interface, providing stability to the emulsion. Adjusting the particle and liquid properties can help achieve this optimal contact angle for enhanced emulsion stability. Many industries benefit from exploiting the potential of Pickering emulsions - e.g., cosmetics, pharmaceuticals, paint and coating, agrochemicals, oil and gas, nanotechnology, environmental, biomedical engineering, textiles, and personal care products. However, due to our limited column space, we will focus today solely on the food industry. ramé-hart instrument company values the substantial number of customers we have in the field of food science. The food science industry benefits from understanding Pickering emulsions in several ways. First, Pickering emulsions offer enhanced stability compared to traditional emulsions, leading to longer shelf life and improved product quality. One example which illustrates how Pickering emulsions offer better stability compared to traditional emulsions is in salad dressings. In traditional salad dressings, stabilizers such as surfactants or proteins are used to prevent oil and water from separating. However, these stabilizers can degrade over time or in harsh storage conditions, leading to phase separation and a shorter shelf life. By contrast, Pickering emulsions use solid particles1 as stabilizers, which form a robust barrier around the oil droplets. This barrier effectively prevents droplet coalescence and phase separation, even under challenging storage conditions. As a result, salad dressings formulated with Pickering emulsions exhibit longer shelf life and improved product quality, maintaining their desired texture and appearance over time.2

Secondly, by utilizing natural solid particles as stabilizers, Pickering emulsions align with clean labeling trends, meeting consumer demand for more natural and transparent food products. The production of mayonnaise makes a good case study. Traditional mayonnaise often uses synthetic emulsifiers like polysorbates or mono- and diglycerides to maintain a stable emulsion of oil and water. However, these synthetic additives can be a concern for health-conscious consumers seeking more natural ingredients. By using natural solid particles, such as finely ground mustard or chia seeds or cellulose fibers, as stabilizers, manufacturers can create a stable Pickering emulsion for mayonnaise.3 These natural ingredients not only provide the necessary stabilization but also appeal to consumers looking for products with simple, recognizable components. This approach helps meet the demand for natural products that align with consumer preferences for healthier, additive-free foods. Lastly, the ability to control the size and distribution of solid particles allows for precise texture manipulation, leading to the development of innovative food formulations with desirable sensory attributes. Low-fat ice cream is a tasty example of this. By carefully selecting and dispersing micro-sized cellulose particles as stabilizers in a Pickering emulsion, food scientists can achieve a creamy texture that mimics full-fat ice cream. The uniform distribution of these tiny particles creates a smooth, rich mouthfeel without the need for high levels of fat, leading to a tasty, healthier ice cream formulation with the desirable sensory attributes of traditional ice cream. Overall, understanding Pickering emulsions empowers food scientists in their effort to offer enhanced stability, longer shelf life, and improved product quality. The food industry benefits significantly from Pickering emulsions through more stable salad dressings, natural ingredient-based mayonnaise, and innovative low-fat ice cream with desirable textures - just to name a few examples of how S.U. Pickering's research over 100 years ago is still making the world a better place. Notes |

| Product of the Month - Model 90 |

The ramé-hart Model 90 is an exceptional

entry-level instrument, carefully designed to meet the needs of students

and researchers seeking an affordable yet robust goniometry solution.

This model excels in ease of use and reliability, making it an ideal

choice for an array of wetting research applications. The Model 90 is

available in two editions to cater to specific research requirements:

Equipped with the U3 Series SuperSpeed camera, the Model 90 ensures high-resolution image capture for accurate and detailed analysis. The DROPimage software facilitates seamless data acquisition and interpretation. Standard backlighting is provided via an LED illuminator, with an optional upgrade to an LED light source with a fiber bundle available for enhanced illumination. The Model 90's reliability and performance have made it a staple in university laboratories and research centers worldwide, serving both large corporations and small enterprises. What's more, every Model 90 is a complete turn-key solution ready to plug-and-play with all required components. For more detailed information, including a PDF brochure and product images, please visit this page. Discover how the ramé-hart Model 90 can elevate your research capabilities. For a quotation for more information, please contact us. |

|

Regards,

Carl Clegg |