|

October

2024 |

| Understanding Surface Treatments |

|

In our previous newsletter1, we explored contact angle line dynamics, which focuses on the movement and behavior of the contact line. This behavior can be adjusted through surface treatments that modify surface energy or roughness, impacting the contact line's mobility and the wetting properties of the liquid. Such treatments can either promote or inhibit the pinning of the contact line, thereby affecting how the liquid spreads or recedes on the surface. In addition to exerting significant influence on the wetting behavior of materials, surface treatments can also often induce wetting transitions from one state to another, such as from a non-wetting (superhydrophobic or hydrophobic) to a wetting (hydrophilic) state or vice versa. These transitions are driven by changes in the surface chemistry or roughness introduced by the treatment process. One example is oxidation. Surface oxidation can increase surface energy, making the surface more hydrophilic. For example, the oxidation of a metal or semiconductor surface can create a thin oxide layer that increases the surface's affinity for water, causing a transition from a hydrophobic to a hydrophilic state. Plasma treatments can introduce polar functional groups (like hydroxyl or carboxyl groups) on the surface, significantly enhancing its hydrophilicity. This is often used to increase the wettability of polymers or glass, shifting them from a non-wetting to a wetting state. Plasma treatment is a versatile and essential tool in microchip fabrication, enabling precise control over surface properties, material deposition, and etching processes. Its ability to operate at lower temperatures and with high precision makes it indispensable in the production of modern semiconductor devices. The ramé-hart Model 400 is the only commercially available contact angle goniometer on the market designed specifically for semiconductor manufacturing.2

Applying a hydrophilic or hydrophobic coating can also induce a wetting transition. For instance, coating a surface with a hydrophobic substance (e.g., fluoropolymer) can make a hydrophilic surface water-repellent, while coating with a hydrophilic polymer can make a hydrophobic surface water-attractive. Another example is coated glass. Glass, by nature, is hydrophilic, meaning the water tends to spread out and a low contact angle results. If the glass is cleaned using a plasma treatment, it can then be coated with a silane-based compound (e.g., trimethylsilyl chloride). This can be done via a chemical vapor deposition (CVD) process, dipping, or spraying. As a result, the glass surface becomes hydrophobic, with water droplets now forming beads that roll off easily. This wetting transition is characterized by an increase in the water contact angle, typically from less than 30° to greater than 90°, indicating a transition from a wetting to a non-wetting state. The most obvious applications for this type of treatment would be to add anti-fogging properties to goggles and windows, make glass surfaces self-cleaning, and improve optical devices such as camera lenses and sensors by preventing water from building up and distorting images and optical transmissions. In conclusion, surface treatments play a critical role in controlling contact angle line dynamics and inducing wetting transitions, offering valuable applications across various industries. From enhancing wettability in semiconductor manufacturing to creating water-repellent coatings for glass, these treatments provide essential functionality for modern technological advancements. Notes |

| Product of the Month - Model 190 |

|

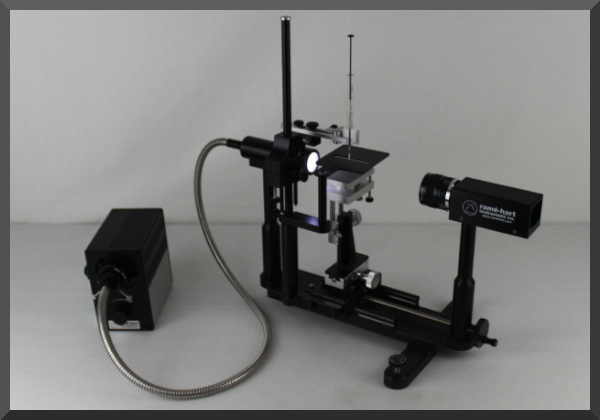

The ramé-hart Model 1901 is equipped with

the same U4 Series SuperSpeed camera as our higher-end models, including

Model 210 and above, which runs at speeds up to 520 fps. In fact, the

hardware across the board is identical. What sets the Model 190 apart is

its software. It comes with DROPimage CA2, a streamlined

application designed specifically for precise contact angle

measurements—without any unnecessary extras.

This model is a top choice for universities and research labs focused solely on measuring the contact angle of a liquid drop on a substrate. The Model 190 now includes ramé-hart’s new LED Fiber Optic Illuminator, delivering optimal backlighting for clear and accurate imaging. Its three-axis stage moves effortlessly along ceramic-coated shafts with Frelon-lined bearings that are maintenance-free and built to last. Precise left-to-right and vertical positioning is achieved through rack-and-pinion movements for smooth operation. The ramé-hart Model 190 is the perfect solution for any research lab seeking reliable, accurate contact angle measurements. Notes |

|

Regards,

Carl Clegg |