|

December 2024 |

| The Role of Contact Angle in Designing Sorbents for Oil Spill Cleanup |

|

Oil spills present severe

environmental challenges, requiring efficient remediation

technologies to minimize ecological and economic impacts. Sorbents,

materials designed to absorb or adsorb spilled oil, are critical

tools in these efforts. The performance of sorbents in oil spill

cleanup is highly influenced by their surface wettability, as

characterized by contact angle measurements. Contact angle—a measure

of the wettability of a surface by a liquid—provides insight into

the sorbent’s hydrophobicity (repellence of water) and oleophilicity

(affinity for oil). These properties determine how effectively a

sorbent separates oil from water and captures spilled oil. Materials

with extreme wettability, such as superhydrophobic (contact angle

>150° for water) and superoleophilic surfaces (contact angle near 0°

for oil), are especially effective in oil-water separation

applications.

Manmade sorbents can be engineered to exhibit both hydrophobic and oleophilic properties, making them ideal for repelling water while effectively attracting and retaining oil. Commonly used materials include polypropylene and polyurethane foams, which demonstrate high water contact angles (>90°) and low oil contact angles (<30°). Researchers in Canada and China have proposed a lignin-based polyurethane/graphene oxide foam due to its exceptional reusability and high sorption capacity, outperforming traditional commercial polypropylene sorbents.1 This superoleophilic and superhydrophobic foam offers a promising solution for oil spill cleanup applications. Although both polypropylene and polyurethane foams are lightweight, highly efficient at absorbing oil from water surfaces, and reusable, their lack of biodegradability raises significant environmental concerns. Wood and plant fibers have been explored as natural sorbents for addressing aquatic oil spills. However, their effectiveness is often limited by their tendency to absorb both water and oil. Researchers at the Pacific Northwest National Laboratory studied how pretreating cotton fibers with fatty acids can enhance their performance as sorbents for crude oil.2 Raw cotton fibers were chemically modified with C18 fatty acids using simple leaving group chemistry. This modification involved altering free surface hydroxyl groups with long alkyl chains, resulting in fibers with increased water contact angles, indicating a significant reduction in surface energy. The modified fibers exhibited a stronger affinity for oil and a corresponding repulsion of water. This behavior translated into greater oil sorption and better water rejection by loose fiber assemblies (e.g., balls or yarn) compared to unmodified cotton. The cotton modification process was simple, cost-effective, and produced a material with high stability, rapid oil sorption, high crude oil capacity, low water retention, and excellent reusability. Similar to natural cotton, the modified fibers can be fabricated into various forms. These characteristics make the treated cotton fiber a promising alternative sorbent for crude oil spill response, with the added environmental benefit of being biodegradable. To optimize sorbent efficacy, material design must strike a careful balance between hydrophobicity and oleophilicity. Advances in material science are focused on modifying surface roughness and chemistry to achieve superhydrophobic and superoleophilic properties. Additionally, incorporating nanostructures enhances surface area and improves control over wettability. By utilizing biodegradable materials, these sorbents can also reduce environmental impact after use. Contact angle is crucial in designing sorbents for oil spill cleanup. Materials with high water contact angles and low oil contact angles efficiently separate oil from water while maximizing sorption capacity. Advances in material science optimize sorbent performance for oil spill remediation. The choice of materials must balance efficacy, environmental impact, and cost to ensure a sustainable solution for protecting aquatic ecosystems. Notes |

| Product of the Month - Certified Fixed Drop Calibration Reference Tool |

|

The ramé-hart

Certified Fixed Drop Calibration Reference Tool p/n 100-27-03 is an

invaluable tool for verifying the integrity of any ramé-hart goniometer

- both new and old. While this tool does not perform the calibration

(for that you will need the

Precision Combo Calibration Device p/n 100-27-31), it will help any

user determine if (a) the instrument is properly calibrated and (b) that

a valid method is being used to collect contact angle data.

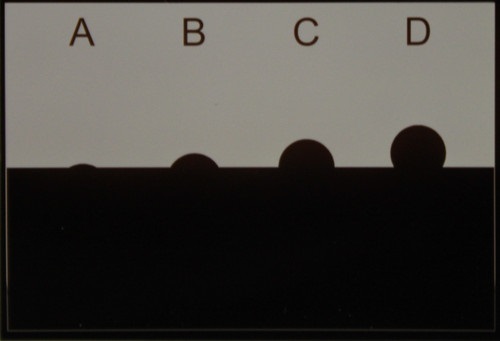

The reference tool has (4) nominal drops with contact angles at 30°, 60°, 90°, and 120° representing both hydrophobic and hydrophilic surfaces. Since the drops are printed on a film that is resistant to shrinking or expanding, the repeatability over time is extremely high. Furthermore, by using this reference tool, you eliminate the many variables that can affect the accuracy and repeatability of a conventional liquid sessile drop on a standard surface - such as contamination, environmental factors, and surface topology. Add this reference tool to your instrument setup for an additional level of assurance that the contact angle results you are collecting are valid. |

|

Regards,

Carl Clegg |