|

September

2025 |

| Superhydrophobic State vs. Lubricant-Infused State |

|

Surfaces that exhibit extreme liquid

repellency have fascinated surface scientists for decades,

leading to the development of two distinct yet equally remarkable

states: the superhydrophobic state and the lubricant-infused state.

While both aim to create non-wetting surfaces, their underlying

mechanisms and resulting properties differ significantly.

The superhydrophobic state, famously inspired by the lotus leaf, achieves its extraordinary water repellency through a delicate interplay of surface roughness and low surface energy. Here, the surface possesses a hierarchical micro- and nano-texture, which, combined with a hydrophobic coating, traps a cushion of air beneath any impinging water droplet. This trapped air layer dramatically reduces the contact area between the liquid and the solid, causing water droplets which already have relatively high surface tension to bead up into nearly spherical shapes with contact angles exceeding 150 degrees.

This state also allows the drops to effortlessly roll off the surface at a low roll-off angle. This phenomenon, often termed the Cassie (or Cassie-Baxter) state, provides excellent self-cleaning properties, as rolling droplets pick up dirt and contaminants. However, this elegant system is not without its weaknesses. The fragile air pockets can be compromised by external pressure or impact, leading to a collapse of the air cushion and a loss of repellency. Furthermore, superhydrophobic surfaces are typically effective only against high-surface-tension liquids like water, failing when exposed to low-surface-tension liquids such as oils, which can easily penetrate the nanotextured topology and wet the underlying surface.

By contrast, the lubricant-infused state, drawing inspiration from the carnivorous pitcher plant, offers a potentially more robust approach to liquid repellency. These surfaces, often referred to as SLIPS (Slippery Liquid-Infused Porous Surfaces), are engineered by infusing a porous solid substrate with a lubricating liquid that is immiscible with the liquid to be repelled. This lubricant forms a stable, molecularly smooth, and defect-free liquid film over the entire surface, effectively creating a perpetually slippery interface. When a liquid droplet lands on a lubricant-infused surface, it slides effortlessly across this liquid layer, completely isolated from the underlying solid topography. This liquid-liquid interface provides incredibly low friction, resulting in minimal contact angle hysteresis and exceptional repellency. Unlike superhydrophobic surfaces, lubricant-infused surfaces exhibit superior pressure stability, as the incompressible liquid layer is far more resilient than trapped air. Moreover, the self-healing nature of the lubricant allows the surface to repair minor damage by simply replenishing the infused liquid. Perhaps most significantly, lubricant-infused surfaces are omniphobic, meaning they can repel a broad spectrum of liquids, including not only water but also oils, organic solvents, and even biological fluids, making them highly attractive for diverse applications ranging from anti-fouling coatings to medical devices. By combining superhydrophobic and lubricant-infused surface technologies, researchers in Taiwan1 have developed a hybrid material with switchable liquid repellency and improved durability. This innovative design uses precise amounts of silicone oil infused into a porous substrate, allowing the surface to transition between states and providing a self-healing mechanism that counteracts physical damage. The new surface significantly outperforms traditional superhydrophobic surfaces, offering a robust solution for applications in harsh environments. While both superhydrophobic and lubricant-infused surfaces offer compelling solutions for liquid repellency, they each represent a distinct engineering philosophy: one relying on a fragile air cushion and the other on a robust, self-healing liquid film. The choice between these states ultimately depends on the specific application's demands for durability, pressure stability, and omniphobicity. |

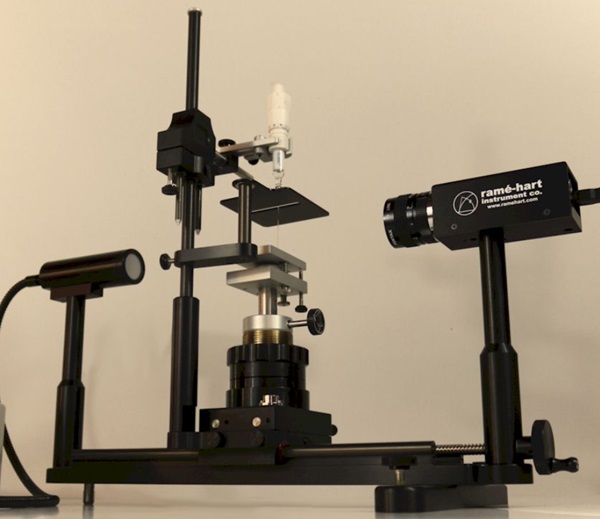

| Certified Pre-owned Products |

|

We currently have a limited selection of certified pre-owned instruments available at significant cost savings. Each unit has been meticulously factory-serviced and recertified to meet our rigorous standards - often incorporating new components and cameras and the latest software to ensure peak performance and reliability. Each also includes the same full one-year warranty that we offer on our new products. These pre-owned products include a Model 260 (p/n 260-U4), Model 400 (p/n 400-U4), Automated Tilting Base (p/n 100-25-A), Environmental Chamber (p/n 100-07), Temperature Controller (p/n 100-50), and Advanced Chamber (p/n 100-26-T). Feel free to contact us today for a no-obligation quotation for any of these certified pre-owned instruments or any other new ramé-hart instrument product. |

|

Regards,

Carl Clegg |