|

Visit our website at

www.customspinnerets.com

|

|

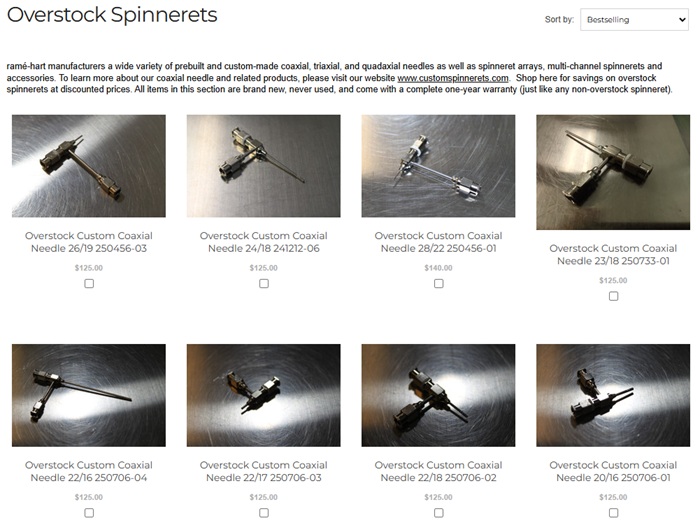

Overstock Spinnerets |

|

Grab a ramé-hart Overstock Coaxial or

Triaxial Needle today and save big. These spinnerets are available on a

first-come, first-served basis and are priced at a significant discount.

Each needle has been checked and tested to ensure it conforms with the

drawing shown in its listing. They're in stock and ready to ship today,

so don't miss out on this limited-time offer! To peruse the current

overstock spinnerets, visit this page:

https://www.ramehart.us/overstock-spinnerets/

|

|

Understanding Core-Shell and Hollow Fibers |

|

At ramé-hart instrument co., we're passionate about enabling cutting-edge research and development through our precision spinneret products. If you're working with electrospinning or bioprinting, you've likely encountered, or are considering, the exciting possibilities of core-shell and hollow fibers. These intricate structures, precisely fabricated using our coaxial and triaxial needles, open up an array of new opportunities in a variety of fields and applications. What are Core-Shell Fibers? Imagine a fiber with two distinct layers: an inner "core" material completely encapsulated by an outer "shell" material. This is a core-shell fiber. The magic happens when two immiscible or semi-miscible solutions are simultaneously extruded or electrospun through a coaxial spinneret – a needle-within-a-needle design. Why are they so powerful? 1. Controlled Release: The most common application. The core can encapsulate drugs, growth factors, or even living cells, while the shell provides a protective barrier and controls the release rate. 2. Enhanced Properties: You can combine materials to leverage their individual strengths. For example, a mechanically robust shell can protect a delicate core, or a conductive core can be insulated by a non-conductive shell. 3. Biocompatibility: A non-biocompatible core material can be made suitable for biological applications by encasing it in a biocompatible shell. 4. Targeted Delivery: Functionalizing the shell surface can allow for targeted delivery of the core contents to specific cells or tissues.

Stepping Up to Hollow Fibers Hollow fibers take the concept a step further by removing the core material after fabrication, leaving a cylindrical lumen (a hollow channel) running through the center of the fiber. These can be created using a coaxial spinneret where the core solution is later removed (e.g., through dissolution or evaporation), or in some advanced bioprinting applications, directly printed with a void. What makes hollow fibers unique? 1. Permeability & Filtration: The hollow structure greatly increases the surface area for filtration, separation, or mass transport. This is critical for applications like artificial organs (e.g., hemodialysis membranes) or water purification. 2. Biomimicry: They can mimic natural capillary structures, crucial for developing complex tissue constructs with integrated vascular networks. 3. Reduced Material Usage: For certain applications, the hollow structure can reduce the amount of expensive or rare core material needed. 4. Encapsulation of Air or Gas: Creating a hollow structure can provide insulation or buoyancy. How ramé-hart Spinnerets Make it Possible Our precision-engineered and hand-built coaxial and triaxial needles are at the heart of fabricating these sophisticated fiber architectures. Our coaxial needles (one concentric channel) are ideal for creating core-shell and subsequent hollow fibers. For even greater complexity, our triaxial and quadaxial needles (three and four concentric channels) allow for the production of multi-layered core-shell structures (e.g., core-shell-shell or even more intricate designs), opening doors to truly innovative materials and biological materials. Each ramé-hart spinneret is designed and manufactured with the utmost precision, ensuring consistent flow and concentricity – critical factors for achieving uniform core-shell and hollow fiber morphology. We offer a wide range of standard prebuilt and custom configurations to meet your specific research needs. To get started go to this page. Go to BOX 1 for our prebuilt coaxial needles and BOX 2 for our Custom Coaxial Needle. And BOX 3 is for our Custom Coaxial Needle with Tubing using push-to-connect fittings. Whether you're developing advanced drug delivery systems, engineering complex tissues, or designing next-generation filtration membranes, understanding the power of core-shell and hollow fibers is key. Partner with ramé-hart instrument co. and leverage our superior spinneret technology to push the boundaries of what's possible.

Visit

www.customspinnerets.com to explore our full range of coaxial and

triaxial needles as well as our Modular Coaxial Needle, Multi-channel

Spinnerets, Arrays, and accessories, and discover how we can help you

achieve your research goals! |

|

Coupon Savings |

|

|

|

Thank you for your continued business. Regards,

Carl Clegg |